Metal Surface Inspection

1, Surface dents and scratches on metal casings

2, Rust spots and indentations on metal sheets

Project Details:

As a crucial component in products like automobiles, home appliances, and consumer electronics, the surface quality of metal casings not only affects appearance and user experience but also plays a significant role in functionality and longevity. For instance, scratches or dents on a car's exterior may compromise the body structure's strength, while rust spots on appliance casings can diminish corrosion resistance. In consumer electronics, even minor scratches on the metal casings of items like smartphones or laptops can immediately reduce their perceived value.

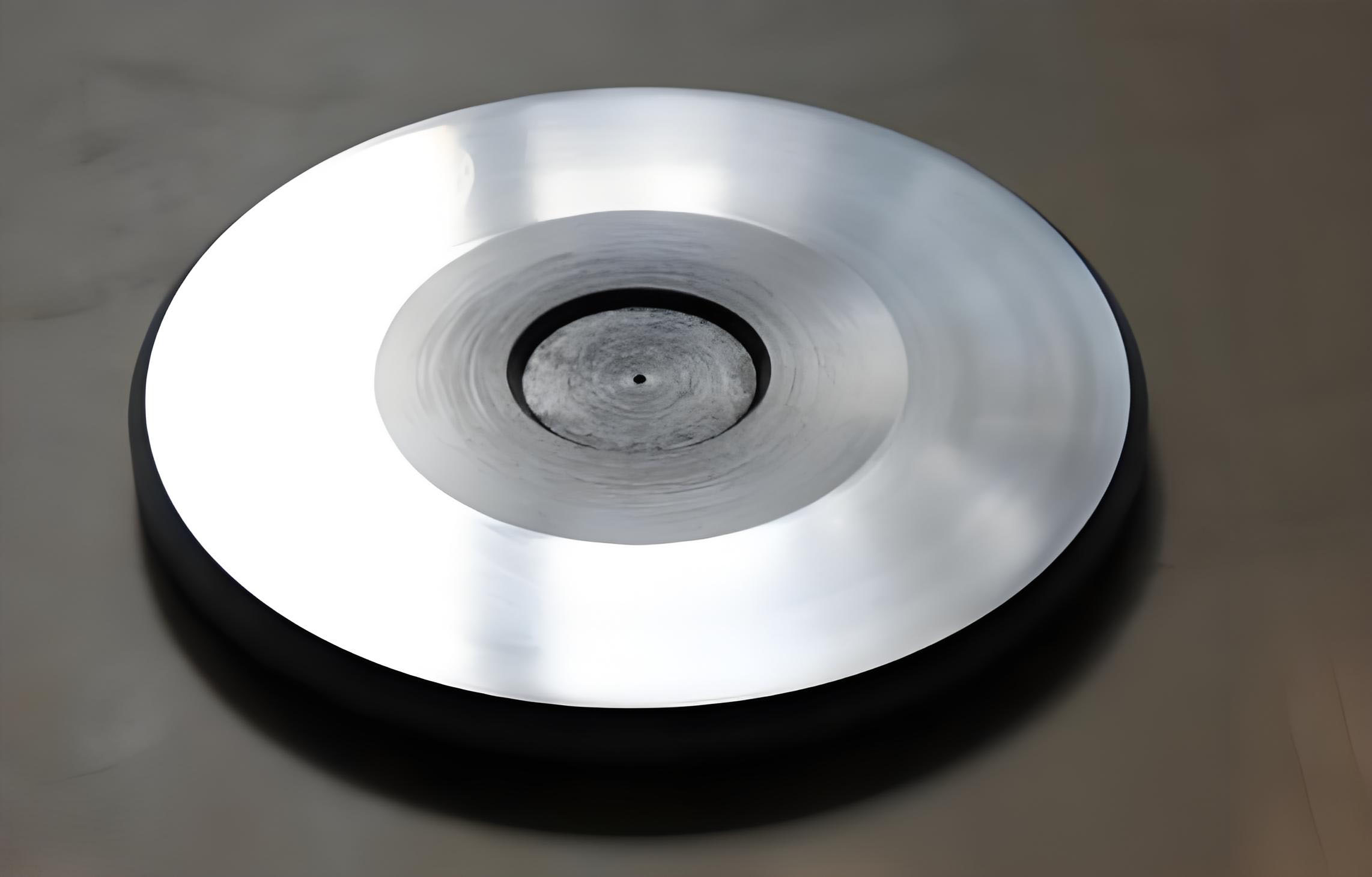

MSTAR combines high-resolution industrial cameras, multi-angle lighting, and deep learning algorithms in a machine vision system capable of precisely identifying defects such as dents, scratches, rust spots, and indentations on metal casings. The system’s design uses ring lighting to highlight scratch characteristics, making fine scratches more detectable in images. Oblique lighting is employed to emphasize surface dents and irregular shadows, ensuring comprehensive inspection. By incorporating preprocessing techniques like noise reduction and image enhancement, the system can process surface features against complex backgrounds, enabling clear capture and analysis of every defect.

The application of machine vision not only helps companies reduce labor costs but also effectively minimizes the risks of missed defects and product recalls, thereby enhancing brand image. As technology advances, machine vision will become increasingly intelligent, providing powerful support for quality control and production optimization in manufacturing.