Reagent Liquid Level Detection

Detection Requirements:

1, Verify that the liquid level of the reagent meets the specified standards

2, The beat is 1 piece/second

3, Accuracy: 1 mm

Project Details:

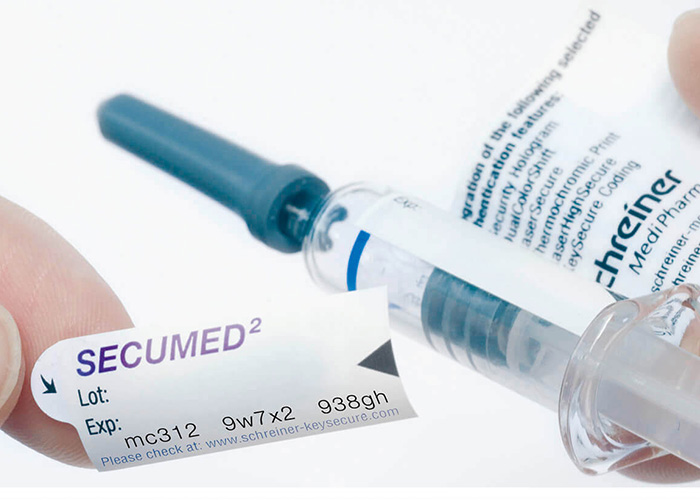

In the pharmaceutical industry, the liquid level within reagent bottles is critical to both the quality of the medication and the safety of patients. Inadequate liquid levels—whether too high or too low—can compromise dosage accuracy and result in non-compliant products entering the market, thereby endangering patient health. Traditional manual inspection methods prove inefficient in large-scale production and are prone to misdetections, highlighting the urgent need for a more efficient and precise detection solution.

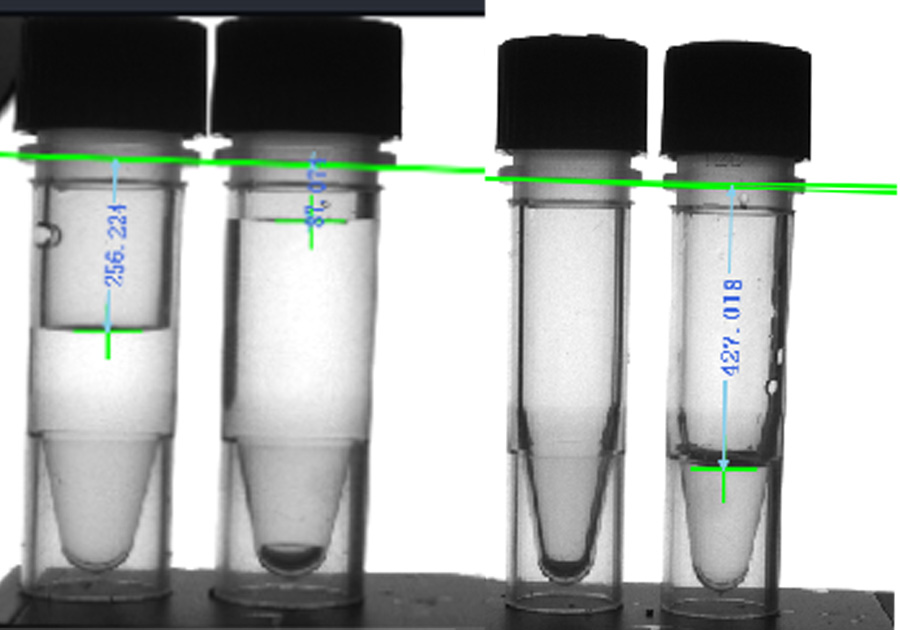

Consequently, a pharmaceutical company has implemented an automated liquid level detection system based on machine vision. This system utilizes high-resolution industrial cameras and advanced image processing algorithms to capture the liquid levels in various types of reagent bottles clearly, identifying liquid boundaries in real time and calculating the height of the liquid. Equipped with precision lighting, the system enhances the contrast between the liquid and the bottle walls, ensuring accurate detection even under varying liquid transparency and color conditions. Furthermore, the system features real-time feedback; upon detecting abnormal liquid levels, it automatically excludes non-compliant bottles, safeguarding against defective products progressing to subsequent stages. Additionally, the system adeptly accommodates a variety of bottle types without the need for frequent adjustments, thus ensuring the efficient operation of the production line.

Since the system's implementation, the pharmaceutical company has significantly improved detection accuracy, with error margins maintained within ±0.1 millimeters. Production efficiency has also markedly increased, enabling the inspection of thousands of reagent bottles per minute. By promptly eliminating non-compliant products, the company has effectively reduced waste rates and saved on production costs. This machine vision-based detection system not only enhances quality control in reagent production but also lays a solid foundation for the future intelligent development of the pharmaceutical industry.