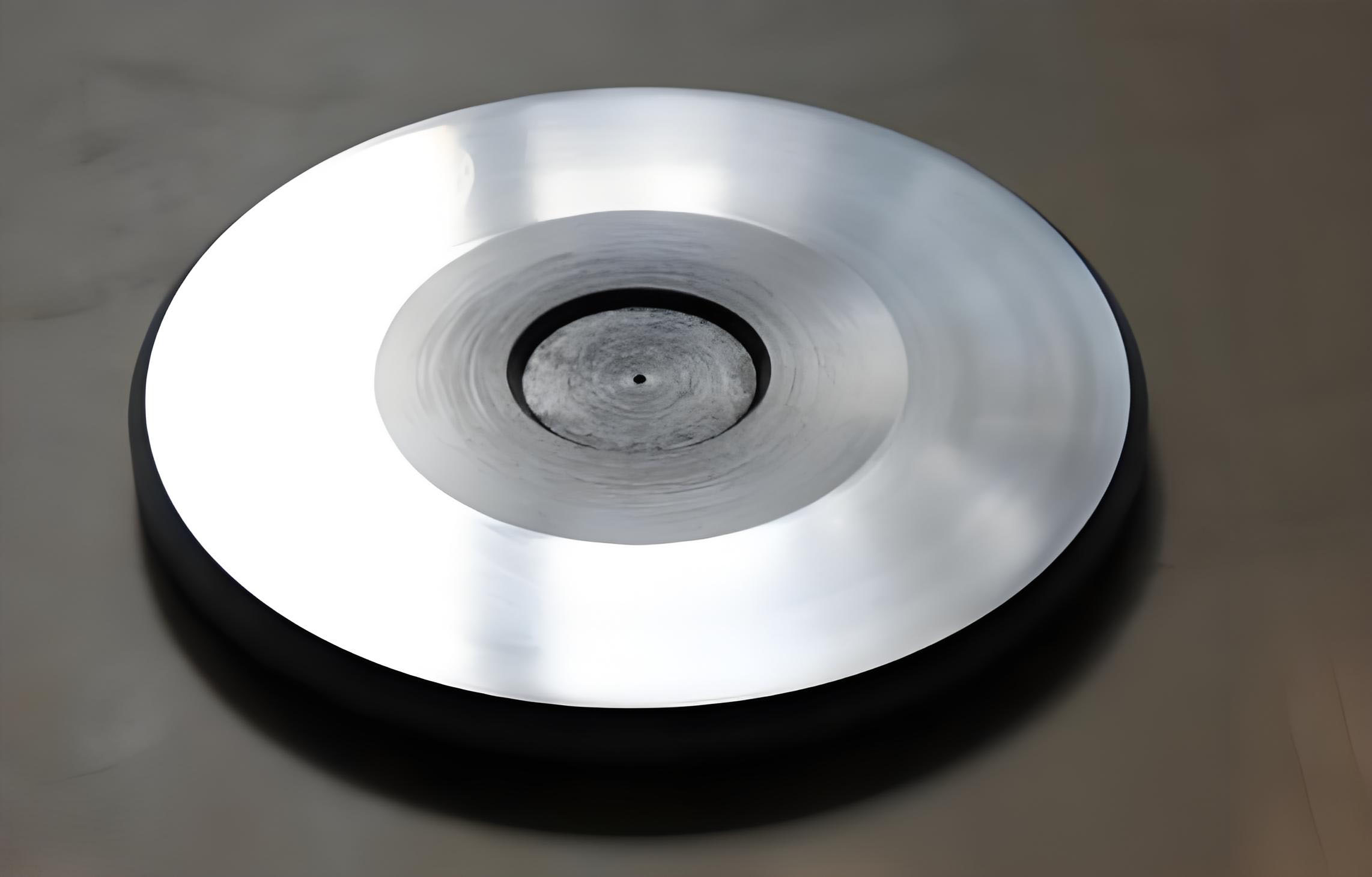

Gear Flatness Detection

Detection Requirement:

1, Gear flatness inspection

2, The beat is1 piece/min

Project Details:

As one of the most common and critical components in mechanical transmission systems, the precision of gears is directly linked to the overall performance and lifespan of the equipment. In many mechanical systems, gears are responsible for transmitting power and altering the direction of motion, requiring exceptionally high manufacturing standards. During the production process, a wide range of parameters must be precisely ensured, including gear dimensions, shape, pitch, tooth profile, and most crucially, flatness. Gear flatness not only affects the fitting accuracy but also impacts noise, vibration, and wear during operation, ultimately influencing the stability and reliability of the entire mechanical system.

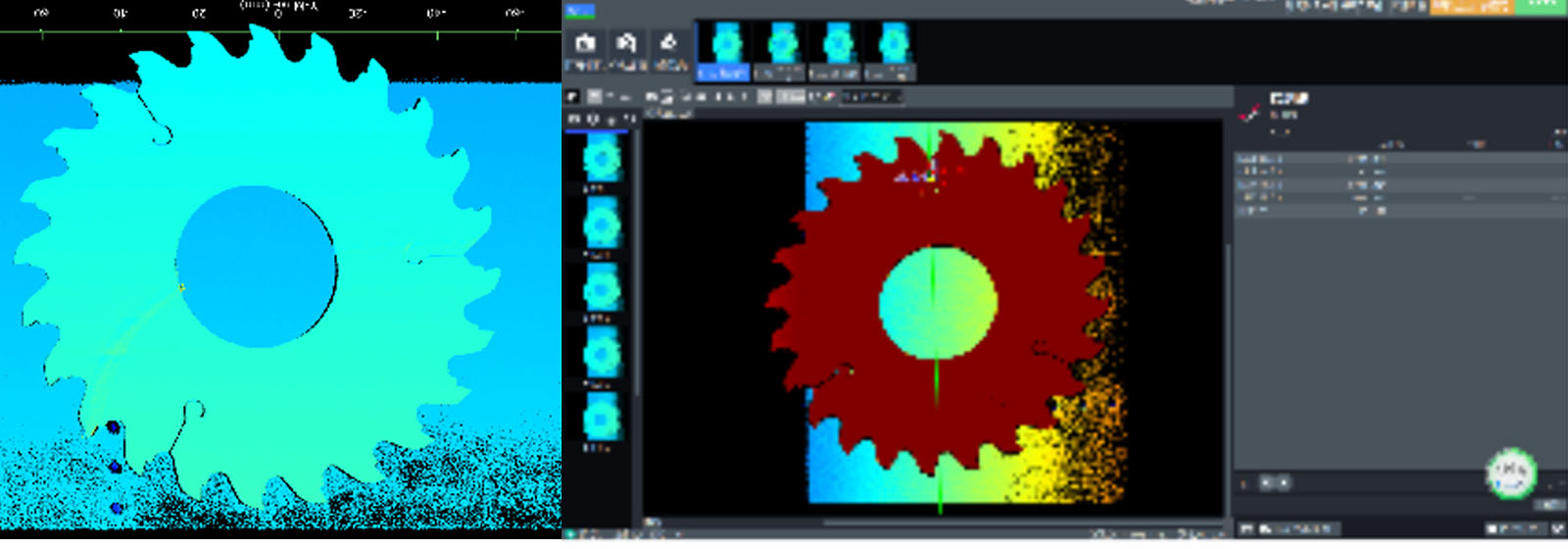

Mstar employs high-precision 3D laser line scanners to swiftly capture the surface geometry of gears, generating detailed point cloud data. This data, processed by specialized software, can automatically compute flatness errors, significantly enhancing detection speed and accuracy. Compared to traditional methods, Mstar’s solution better caters to modern manufacturing’s demands for high efficiency and precision, assisting companies in effectively controlling product quality and reducing rework and scrap rates.