Aluminum Foil Seal Inspection

Detection requirements:

1, Aluminum film sealing bias ≧0.5mm, aluminum film folding edge ≧1mm, aluminum film weak sealing leakage ≧1mm, aluminum film sealing reverse

2, Beat 1S/1 bottle

3, Straight chainway after film sealing machine

Project Details:

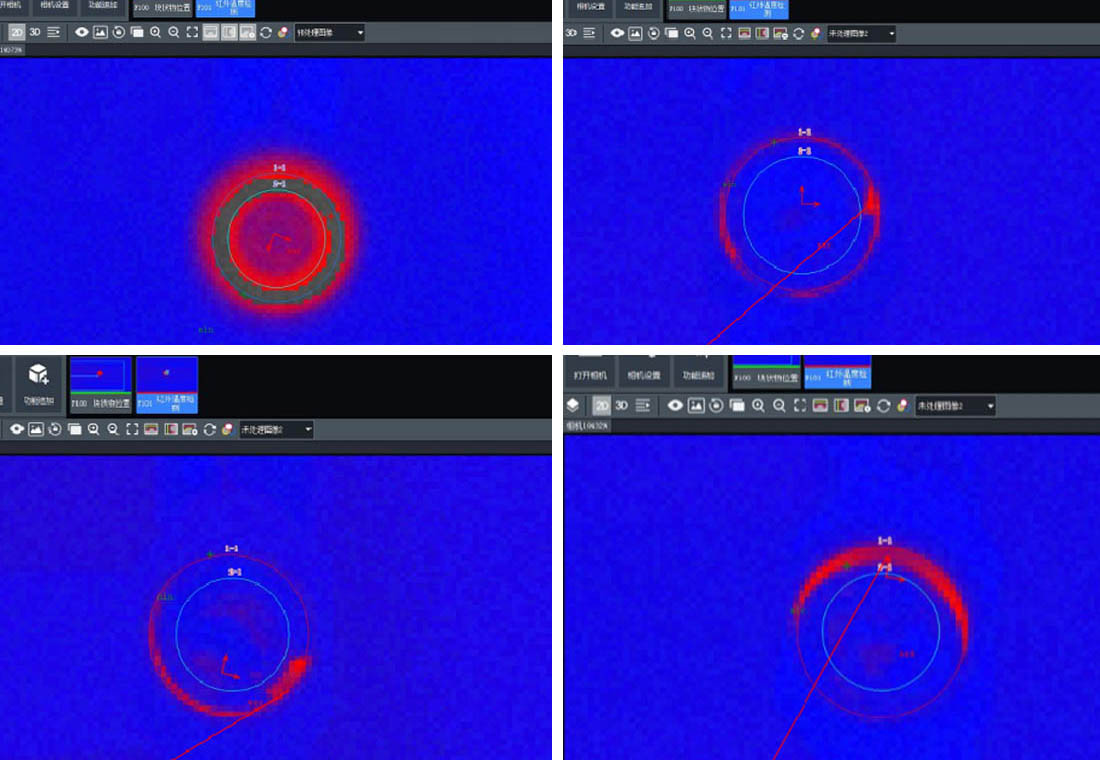

For products with aluminum foil seals or electromagnetic induction seals, the limitations of the human eye and ordinary cameras make it impossible to penetrate the cap or aluminum film to directly observe the condition of the aluminum foil seal. This obstacle to observation makes it difficult for conventional inspection methods to ensure the quality of the seal. However, with the rapid development of infrared thermography, the use of thermal imaging and visual image processing technology for product inspection has become a mainstream trend in the industry.

By capturing and analyzing the distribution of product temperature, infrared thermography can effectively assess the quality of aluminum film sealing. Specifically, thermal imagers can detect temperature changes in the sealing area to detect poor seals, leaks or other defects. This method not only penetrates the cap and aluminum film, but also provides a high-resolution image of the sealing condition in real time, providing a reliable means of quality control for the production line.

Through the application of infrared thermal imaging and visual image processing technology, companies are able to dramatically improve the accuracy and efficiency of closure inspection, reduce the rate of defective products, and safeguard the consistency and safety of product quality. The development and application of this technology not only enhances the automation level of the production process, but also marks an important advancement in quality inspection technology, which further promotes the technological upgrading and innovation of the entire industry.