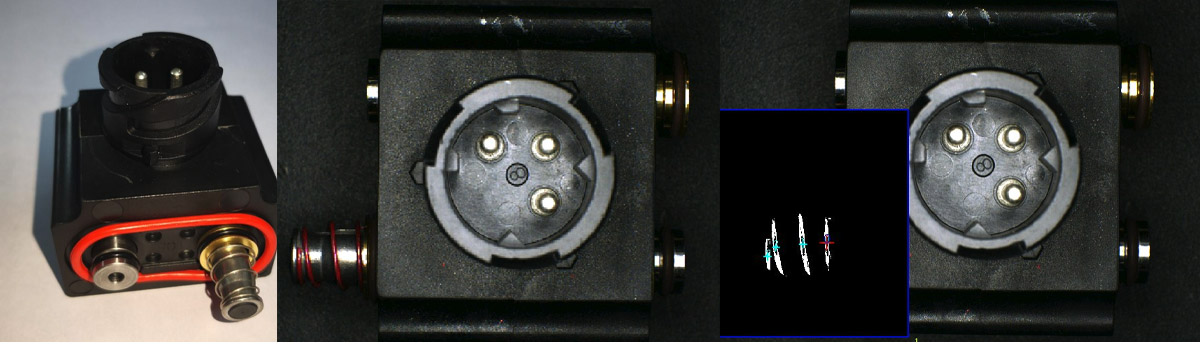

ABS Regulator Detection

Detection Requirements:

1, The electromagnetic valve body is available in three color variations: black base with black head, blue base with black head, and black base with red head, all of which share identical dimensions. The system must automatically recognize these variations

2, The small sealing rings come in two types with the same color; detection of presence is sufficient

3, The large sealing rings are uniformly red following modifications; detection of presence only is required (sample dimensions are incorrect, but subsequent sealing rings can be properly embedded in the electromagnetic valve)

4, Identification of springs includes both presence and color, with consideration for possible rotation or varied placement during the recognition process

Project Details:

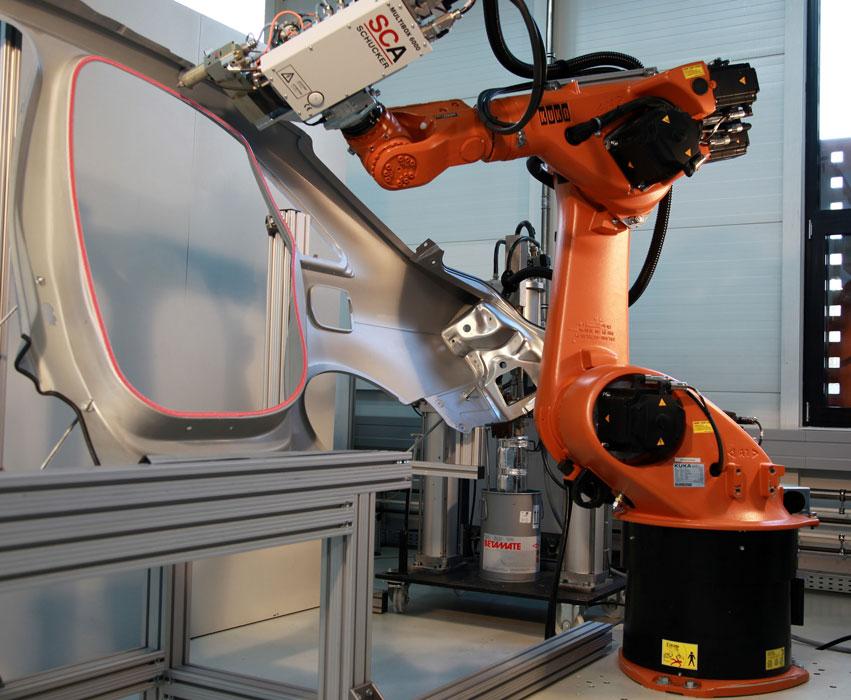

During the automotive manufacturing process, the regulator within the Anti-lock Braking System (ABS) is a crucial component for ensuring braking safety, while the sealing ring plays a vital role in preventing fluid or gas leaks, thus safeguarding the system's normal operation. Due to the small size and concealed placement of the sealing ring, traditional manual inspection methods are prone to oversight or misidentification, posing a risk to product quality. To address this issue, many companies have adopted machine vision technology.

The sealing ring presence detection system, based on machine vision, utilizes high-speed cameras and image processing algorithms to automatically identify whether the sealing ring in the ABS regulator is correctly installed. This system not only accurately detects the presence of the sealing ring but also identifies issues such as poor assembly or positional displacement. Throughout the detection process, the system ensures efficient operation of the production line and consistency in product quality through automatic alarms and real-time data recording.

Compared to traditional inspection methods, the Mstar machine vision system offers advantages of high precision, rapid speed, and remarkable consistency, while enabling data-driven management that supports quality traceability. This technology significantly enhances the detection efficiency and reliability of automotive brake system components, providing robust support for the intelligent and automated development of the automotive manufacturing industry.