Detection of Adhesive on PCB Boards

Inspection Requirements:

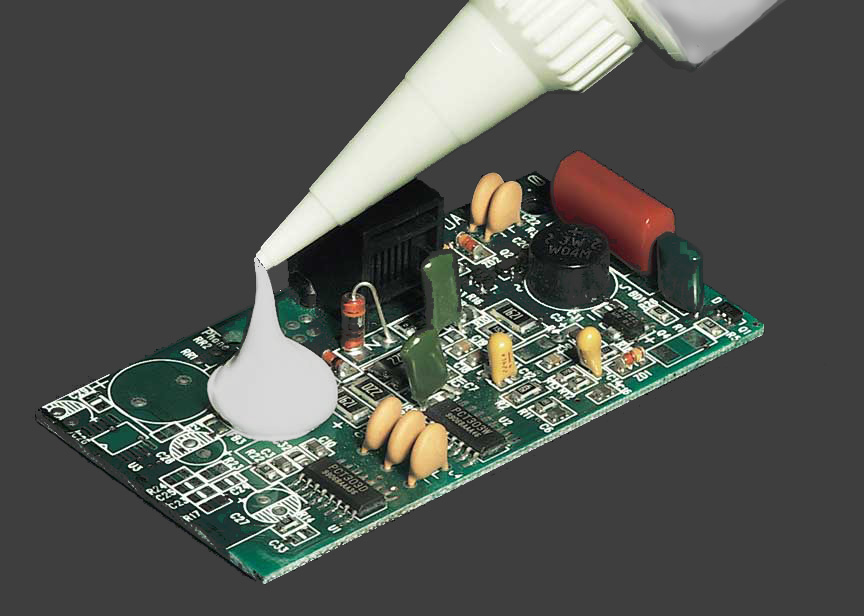

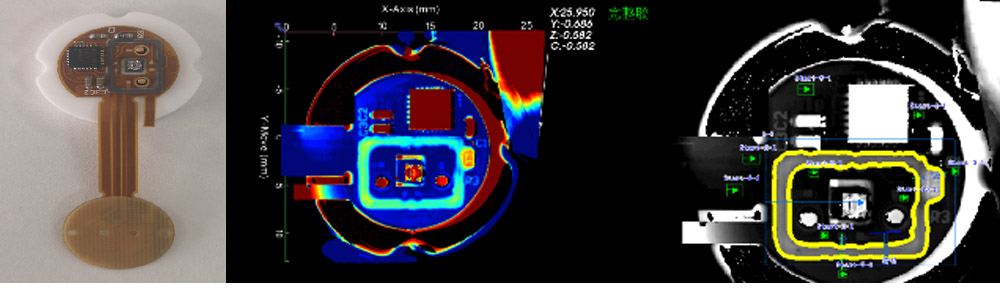

1, Visual inspection of PCBs to detect the presence of adhesive, adhesive breaks, offset, and width.

2, The beat is 1pcs/s

Project Details:

In the production of printed circuit boards (PCBs), ensuring the precision and uniformity of adhesive application is of paramount importance. The adhesive plays a crucial role in PCB manufacturing, serving not only to secure components but also directly influencing the reliability of electrical connections and the overall performance. Any inconsistencies in adhesive application—whether insufficient, excessive, or uneven—can lead to circuit board short circuits, open circuits, and may even jeopardize the normal functioning of devices. Therefore, quality control of the adhesive is vital to the ultimate performance of the PCB.Traditional inspection methods often rely on manual visual checks or basic machine vision systems, but these approaches struggle to accurately identify issues on high-speed production lines with complex coating patterns. The intricate and smooth surfaces of PCBs, coupled with the gloss and reflective properties of the adhesive, present significant challenges for conventional visual systems when assessing adhesive application. Moreover, as production volumes increase, manual inspections not only become inefficient but are also prone to oversights and misjudgments, thereby compromising product quality and reliability.

We employ high-precision 3D cameras to capture real-time three-dimensional data of PCB surfaces. This system effectively detects minute variations in adhesive application and accurately identifies its distribution. Utilizing structured light technology, the system thoroughly analyzes adhesive thickness, coverage, and uniformity, rapidly identifying any anomalies such as missing, excessive, or uneven application.