Automotive Stamping Die Inspection

Inspection Requirements:

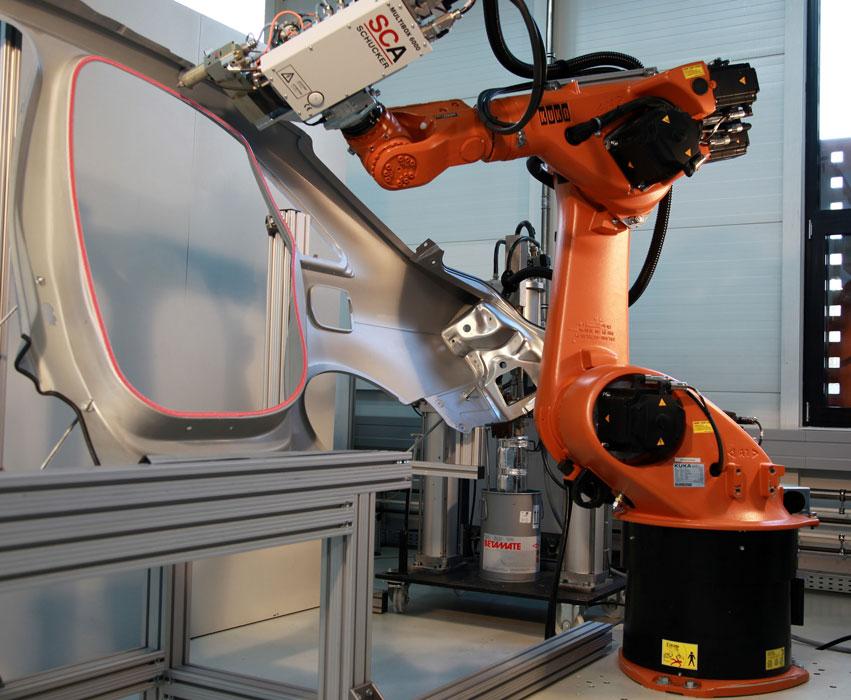

1, Utilize a 3D line-scan camera to pinpoint product locations on the production line, guiding the robotic arm for retrieval.

2, The beat is approximately 24 pieces per minute.

Project Details:

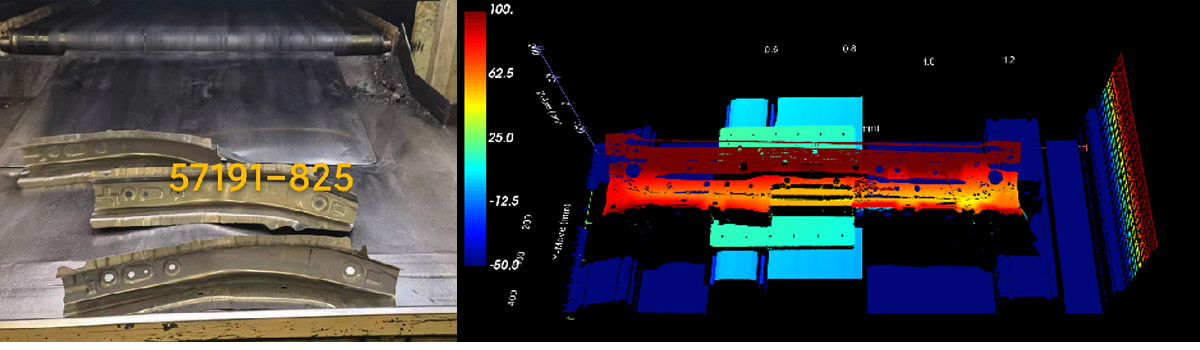

In the automotive manufacturing process, the quality of stamped components directly impacts the structural integrity and assembly precision of vehicles. The removal of stamped metal sheets or parts from the press is a critical step in the processing of automotive components, requiring both speed and accuracy. Improper handling not only risks deformation or damage to the workpiece but may also disrupt the continuous operation of the press, thereby affecting production efficiency. However, due to the intricate shapes of stamped parts and the rapid pace of the removal process, traditional manual operations and 2D vision systems struggle to provide effective and safe management.The smooth and reflective surfaces of metal workpieces present challenges for visual systems, while the varying sizes, shapes, and orientations of different parts further complicate matters. These factors render conventional mechanical grasping methods inadequate to meet the complexities of production demands, while manual removal is limited in speed and prone to errors, increasing the risk of workpiece damage and personnel injury.

To address this issue, we have implemented 3D machine vision technology to achieve automated management of die removal. The system employs high-precision 3D cameras to capture real-time three-dimensional data of the workpieces, accurately capturing shape, position, and angular information. The 3D machine vision system works in concert with automated robotic arms, enabling rapid calculation of optimal grasping points and real-time adjustments to the grasping path, even in the case of randomly stacked or misaligned workpieces. The application of deep learning algorithms enhances the system's ability to identify various types of components, allowing it to adapt automatically to changes on the production line, thereby reducing the risks of misjudgment and damage.