Metal bottle cap dent detection

Detection requirements:

1, Detect whether the bottle cap is crooked cap, broken or pitted

2, The beat is 6 bottles/second

Project Details:

In the whole process of assembling and using metal bottle caps, due to a variety of factors, making the caps may produce a variety of defects. These factors include defects in raw materials, aging of equipment, improper operation of employees and so on. Common bottle cap defects include pressure points, crooked caps, broken rubber rings and other problems. These defects not only affect the appearance of the cap, but also may affect its sealing performance and service life, which in turn affects the overall quality of the product and user experience.

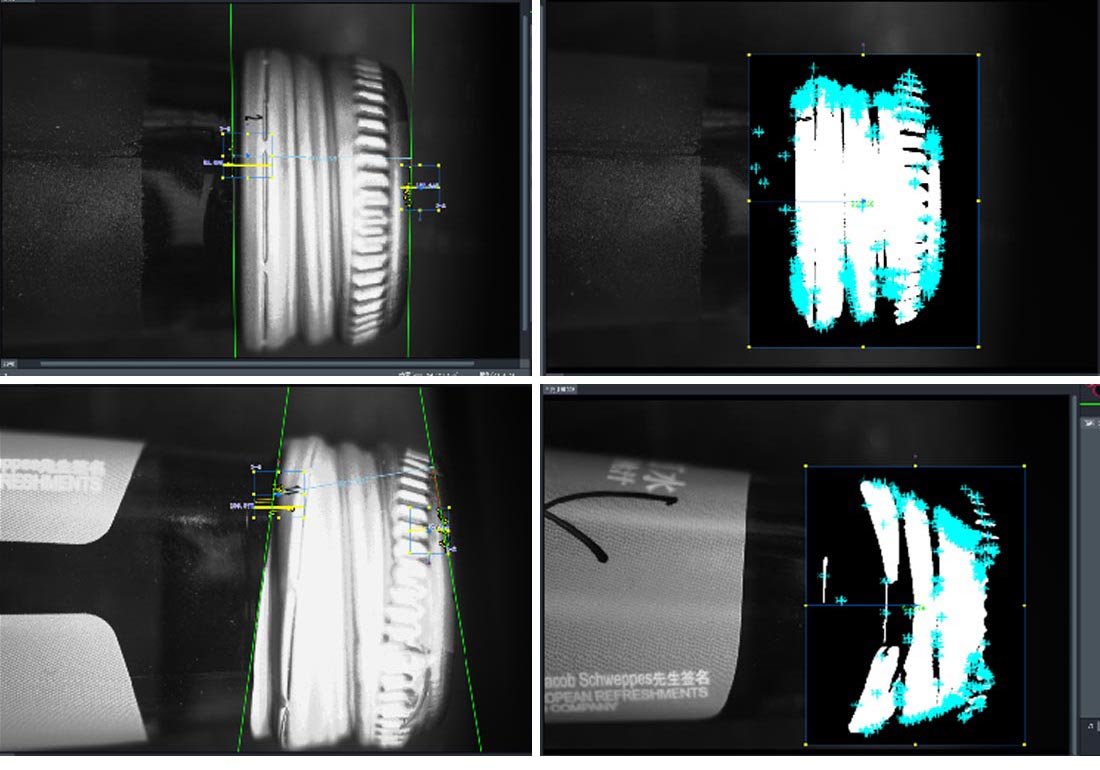

To solve these problems, the project team decided to use a series of advanced inspection and rejection techniques to improve the quality and production efficiency of bottle caps. First, by detecting the angle of the line underneath the cap, it is possible to accurately identify crooked caps. Utilizing high-precision sensors and image processing technology, each cap is inspected in real time to ensure that only the caps that meet the standards move on to the next process. This not only reduces the rate of defective products, but also reduces the workload and errors of manual inspection.

Secondly, the project also introduced AI technology to reject pits on the surface of bottle caps. By training the AI model to identify the pressure points and pits on the surface of bottle caps, unqualified caps are automatically rejected.The introduction of AI technology not only improves the accuracy and speed of inspection, but also improves the ability to identify new defect types through continuous learning and optimization.

To summarize, by detecting the line angle underneath the bottle cap and introducing AI technology to reject pits on the surface of the cap, the project team effectively solved a variety of defects that may occur in the production process of bottle caps. The application of these technologies not only improves the quality of the products, but also brings higher production efficiency and market competitiveness to the enterprise.