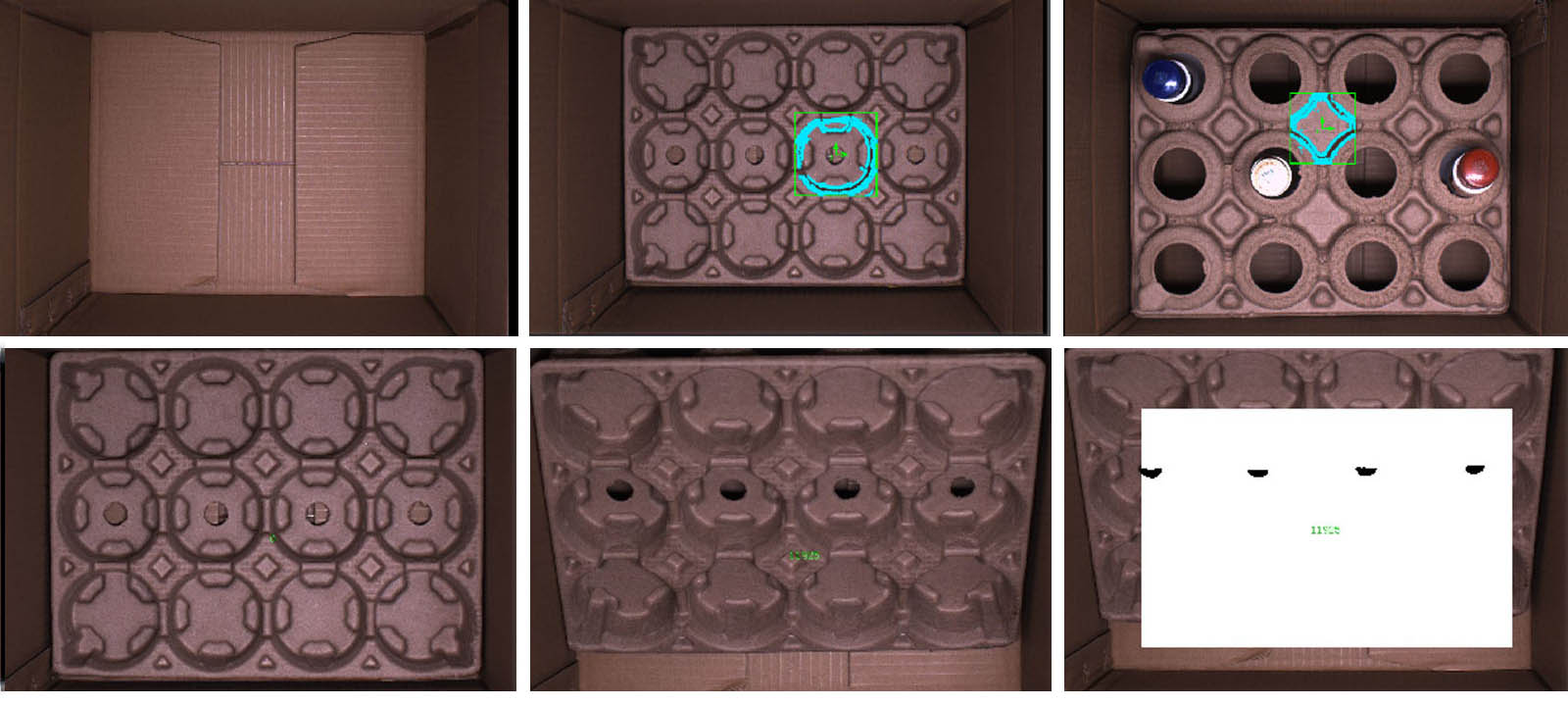

In-box accessory inspection

1, Identification of the presence or absence of the bottom plate in the box, with or without inclination

2, identify the presence or absence of the top plate in the box, with or without tilt

3, identify the presence or absence of pearl cotton in the box

4, the beat is 20 boxes / minute

Project Details:

In an automated production process, each box is made up of several key accessories. However, as fittings may be missing or tilted, this may directly lead to errors or even damage to the product during the cartoning process. To address this challenge, it becomes crucial to introduce machine vision technology to inspect the accessories prior to cartoning.

The project utilizes advanced machine vision technology, specifically the contour tool positioning feature. This technology allows the system to accurately detect the integrity and correct position of each accessory inside the box before it is boxed. This is done by comparing the shadows created by tilting the fittings against the normal condition of unshadowed pearl cotton, thus accurately identifying and rejecting any potentially problematic products.

Through this method, not only is the operational precision and efficiency of the cartoning process improved, but the safety and integrity of the product during transportation and storage is also effectively safeguarded. This highly automated and accurate cartoning inspection system effectively reduces the risk of cartoning errors and product damage, providing a solid guarantee for the smooth operation of the production line.