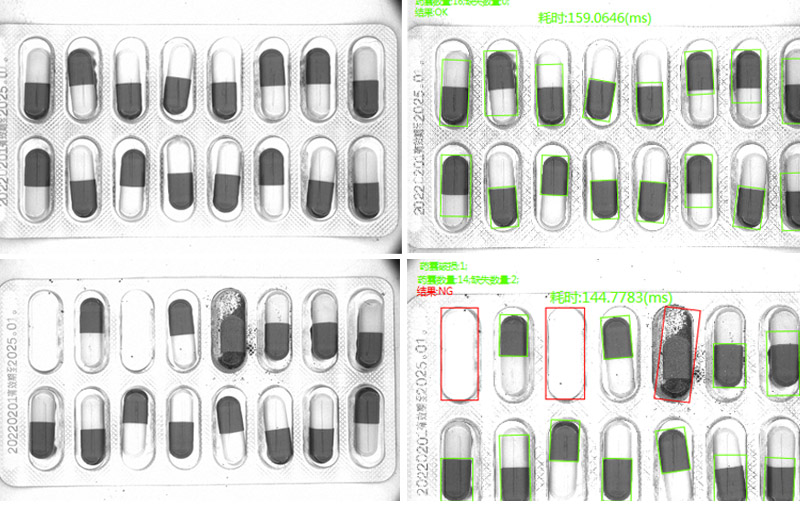

Capsule Defect Detection

Detection Requirements:

1, The beat is 6 pieces/s

2, Accuracy: 0.5mm

Project Details:

In the pharmaceutical industry, the quality of capsule production is crucial, as each capsule impacts patient health and treatment efficacy. The manufacturing process is complex, involving precise formulation and multiple stages, including shaping, sealing, labeling, and packaging. Any error can lead to defects, affecting medication safety and effectiveness. Therefore, ensuring that every capsule meets strict quality standards is essential for compliance and patient safety.

During production, particularly in automated packaging, issues such as inaccurate counts, visual defects, or seal failures often occur, which may not be immediately detected. This can compromise product integrity, leading to recalls and significant financial and reputational damage. Traditional manual inspection is inefficient and subjective, highlighting the need for precise automated systems.

Mstar's automated vision inspection system utilizes advanced AI technology to conduct rapid, accurate inspections in high-speed environments. High-resolution cameras and intelligent algorithms capture and analyze each capsule's appearance, identifying defects such as breakage or seal failures. The system also calibrates packaging quantities to ensure accuracy, preventing defective products from reaching the market.

By adopting Mstar's solution, pharmaceutical companies can enhance operational efficiency, reduce recall costs, and improve product quality, ultimately ensuring greater safety for consumers.