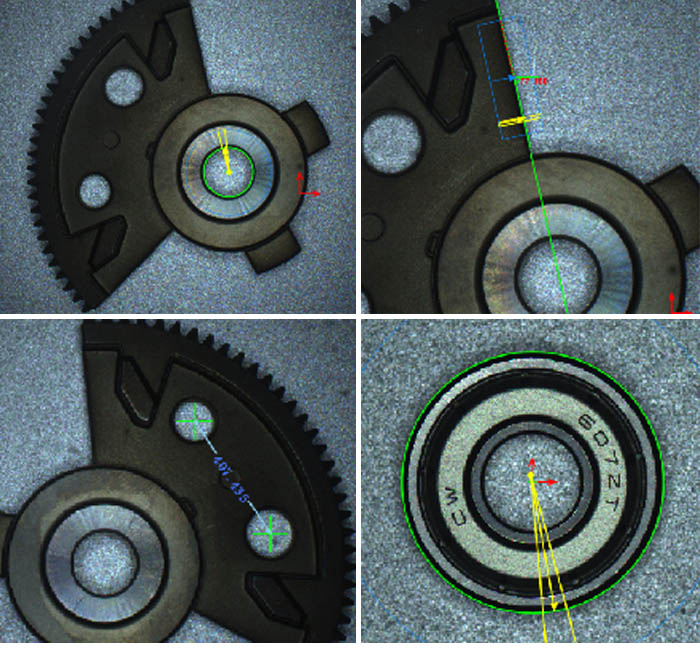

Dimensional Inspection of Metal Components

Detection Requirement:

1, Measuring circular diameter, center-to-center distance, angularity, etc.

2, The beat is 1 piece per second

3, Accuracy: 1 mm

Project Details:

In modern manufacturing, the precise measurement of metal components is essential for ensuring both product quality and performance. As industrial technologies continue to advance, the demand for highly accurate and reliable metal parts grows increasingly prominent. This is particularly true for components requiring precise measurements of key dimensions such as circular diameter, center-to-center distance, and angularity. Accurate measurement of these parameters not only impacts the assembly and functionality of the product but also has a direct bearing on the overall quality and user experience. Even the slightest measurement error can lead to poor assembly, consequently affecting the product’s overall performance and customer satisfaction. Therefore, ensuring the accuracy and consistency of measurements has become a critical aspect of modern manufacturing processes.Mstar's measurement solutions provide rapid, precise measurements of critical dimensions in metal parts, including circular diameter, center-to-center distance, and angularity. Standing out with its exceptional technical capabilities, the Mstar system offers not only high precision and repeatability, guaranteeing consistent standards with every measurement, but also real-time data feedback, enabling operators to promptly identify and rectify potential issues. Additionally, the application of Mstar's measurement solutions plays a pivotal role in quality control, ensuring that the final product not only meets design specifications but also satisfies the high expectations of consumers.