Cookie Damage Detection

Detection requirements:

1, Detect if cookies are damaged

2, The beat is 6 pieces per second

Project Details:

Quality assurance in food manufacturing is paramount. Traditional inspection methods reliant on human judgment are inefficient, prone to errors, and labor-intensive. Damaged cookies fail to meet aesthetic and structural standards, directly compromising overall product quality and potentially impacting consumer perception and satisfaction, thus affecting brand image and market competitiveness.

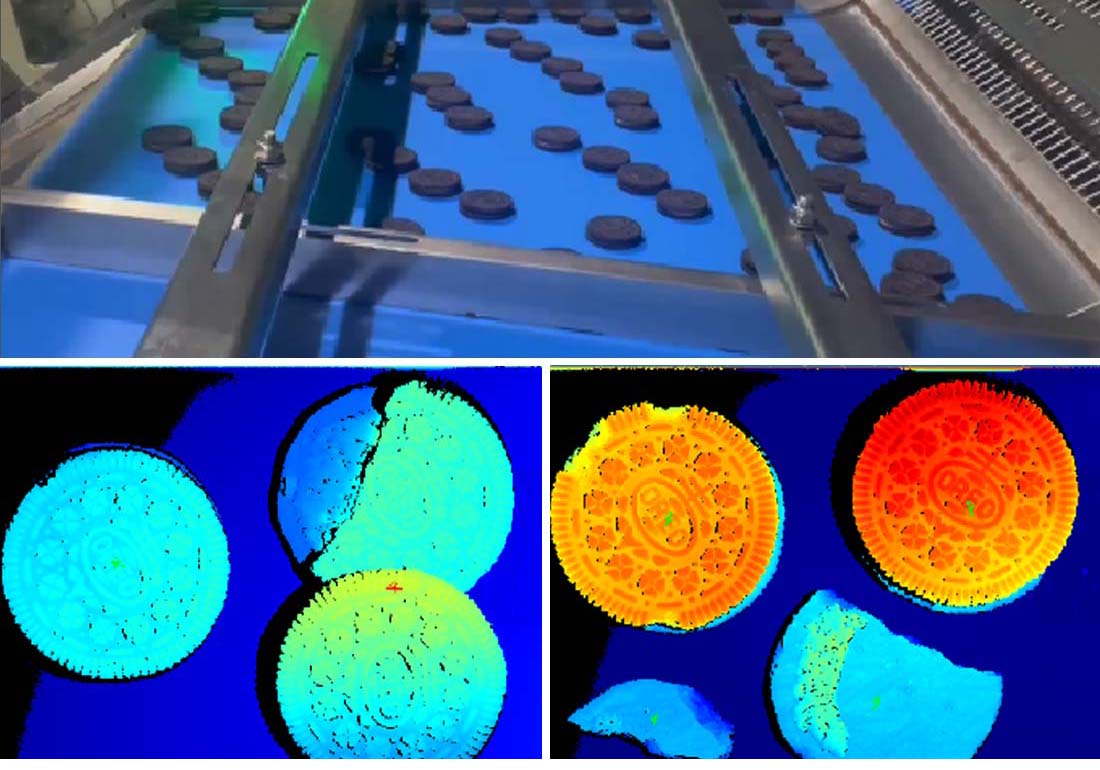

While 2D machine vision has improved production speed and efficiency, it has limitations in measuring cookie thickness, detecting cracks and minor misalignments, leading to missed or false detections. This project employs advanced 3D camera technology to non-invasively acquire point cloud images of products. Through high-fidelity color rendering and precise point cloud visualization, we generate comprehensive 3D images of each cookie, revealing detailed surface features and structural intricacies.

Utilizing advanced height and edge detection tools, we can accurately identify and analyze any damage on the cookie surface, including cracks, fractures, or other structural defects. This precise inspection method enhances the accuracy and reliability of product testing, effectively reducing the production and circulation of damaged products, thereby improving production efficiency and lowering costs. By implementing such advanced technology, enterprises can ensure that every product leaving the factory meets stringent quality standards, fostering consumer trust and maintaining a competitive edge.