Button Battery Inspection

Inspection Requirements:

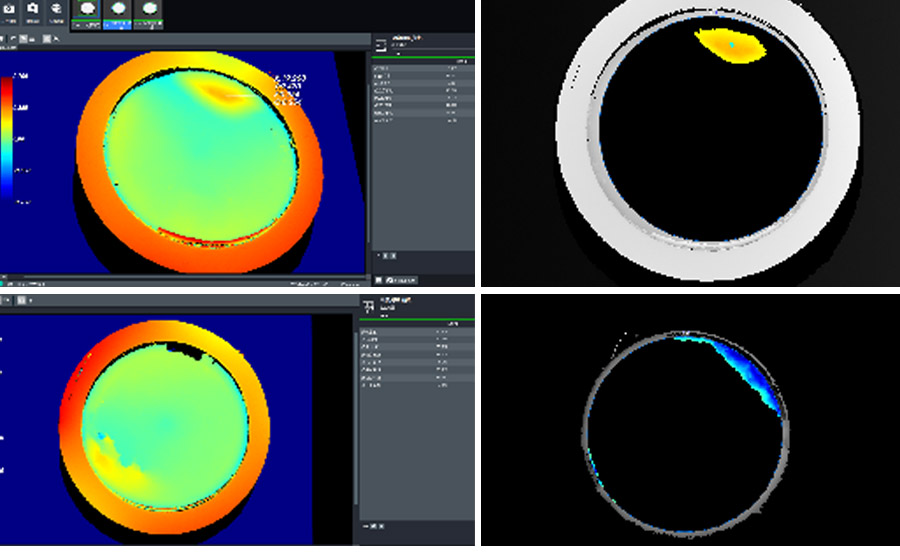

1, By conducting a thorough analysis of the 3D data, ascertain the presence of protrusions or depressions on the battery surface

2, The beat is 1pcs/2.5S

Project Details:

During the manufacturing process of button batteries, ensuring the integrity of the battery's surface is of paramount importance. The battery casing is typically sealed with the electrodes and electrolyte, and surface irregularities such as protrusions, depressions, and scratches can significantly impact both the performance and safety of the battery. These defects may not only lead to leakage or short circuits but can also disrupt the normal operation of devices.

Given the smooth and reflective nature of the battery surface, conventional inspection methods often struggle to accurately identify minor irregularities. Even with machine vision technology, the system's detection capabilities can be constrained by complex lighting variations and the diversity of defect types. Furthermore, the rapid production speed of button batteries renders manual inspection inadequate to meet the demands of large-scale production, resulting in frequent oversights.

To address this challenge, we employ high-precision 3D cameras to capture real-time three-dimensional data of the battery surface, effectively detecting minute surface variations and enhancing both accuracy and efficiency. Utilizing laser scanning or structured light technology, the system can meticulously analyze height information, swiftly identifying various defects, including those that traditional methods may overlook. This innovation not only augments the accuracy of inspections but also significantly enhances the operational efficiency of the production line, ensuring that every battery leaving the factory adheres to stringent quality standards. Through these advancements, our manufacturing process becomes increasingly efficient and reliable, enabling us to deliver superior products to our customers and strengthening our competitive edge in the market.