Localization of Brake Disc Screws

Detection Requirements:

1, Rapid and accurate localization of pre-tightened screws on the front and rear axles and chassis, guiding the robotic arm for automatic screw locking.

2, Achieving automatic screw locking to replace manual operations.

Project Details:

In the automotive manufacturing process, the localization of brake disc screws is a critical phase that directly influences the vehicle's braking performance and overall safety during operation. The brake disc, as the core component of the automotive braking system, necessitates precise installation of its screws to ensure system stability and reliability. However, traditional manual assembly methods often suffer from the uncontrollable nature of human factors, leading to issues such as missed installations, loose screws, or improper placements, which result in inconsistent assembly quality. This not only jeopardizes the safety performance of the vehicle but may also escalate rework and maintenance costs.

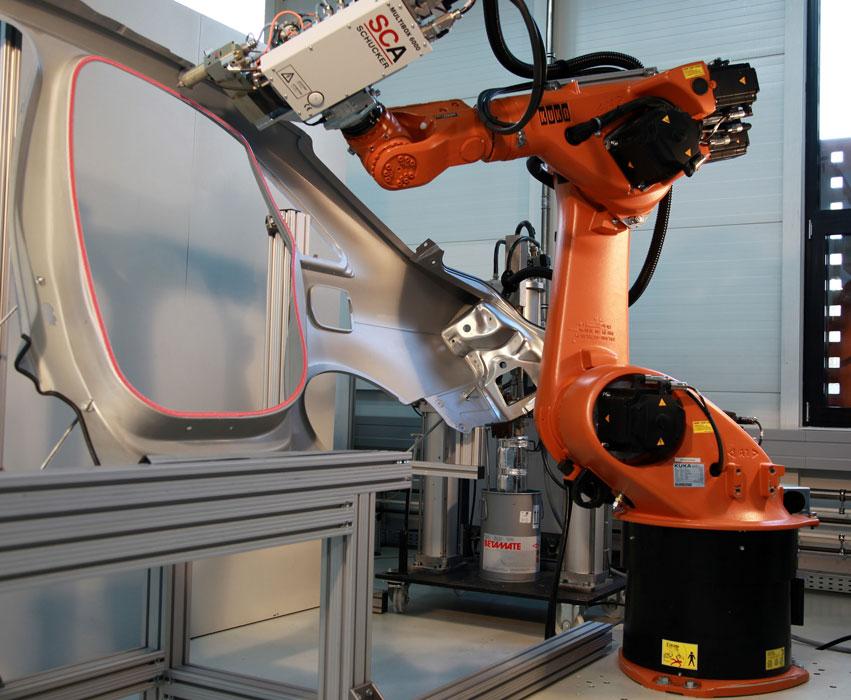

This system utilizes high-precision industrial cameras to capture real-time images of the brake disc from every conceivable angle, ensuring that no detail is overlooked. Equipped with Mstar machine vision software, the system employs image processing technology to accurately identify the location of each screw hole and generates precise coordinate information for the screws based on the recognition results. This guarantees that the positioning of each screw is impeccably accurate, eliminating any misalignment or assembly errors. Furthermore, the system features real-time feedback capabilities. When deviations in screw positioning are detected during the assembly process, the system can promptly self-correct and automatically adjust the screw's position, ensuring that each screw is securely fastened in the correct hole. Additionally, the system continuously monitors the tightening status of the screws to prevent any instances of incomplete fastening or loosening, effectively eradicating issues such as missed installations and poor assembly.

This machine vision-based automated screw localization system not only enhances assembly precision and production efficiency but also provides robust technical support for quality control in the automotive manufacturing industry.