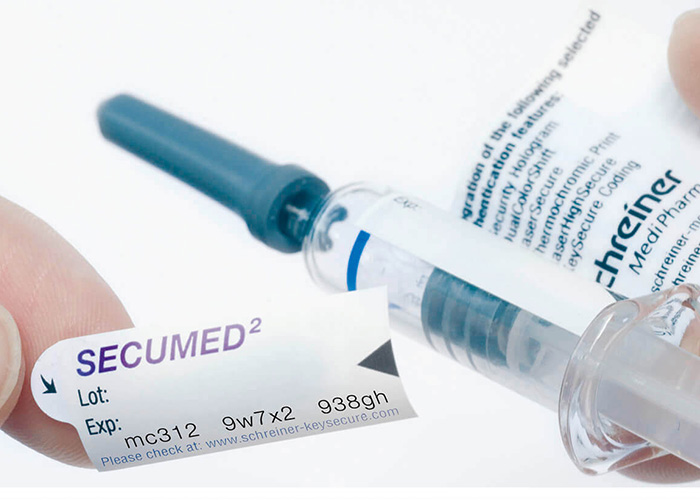

Syringe Scale Line Inspection

Inspection Requirements:

1, Detect issues such as blurriness, ghosting, and breaks in the scale on the outer surface of syringes through visual imaging

2, The beat is 300 pcs/min

3, Precision: 0.03 mm

Project Details:

In the medical device industry, syringes are among the most commonly used drug delivery tools, where the clarity of the scale on their outer surface directly influences the accuracy of medication dosages. Defects such as blurred, double, or broken lines can lead healthcare professionals to misinterpret the volume of liquid, ultimately affecting patient treatment outcomes and safety. Traditional manual inspection methods often rely on the operator's experience and are prone to oversight and misjudgment, particularly on high-speed production lines. To address these challenges, a medical device manufacturer has opted to implement an automated inspection system based on machine vision to ensure the quality of syringe scale markings.The clarity of syringe scale markings is crucial in the medical device sector, as it directly impacts the precision of drug dosages and, consequently, patient care. However, conventional manual inspection methods are susceptible to errors in high-speed production, failing to guarantee that every syringe's scale conforms to established standards. To mitigate this issue, a medical device manufacturer has adopted a machine vision-based automated scale inspection system.

This system is equipped with high-resolution industrial cameras capable of capturing intricate details of the scale lines, employing advanced image processing algorithms to identify defects such as blurriness, ghosting, and breaks in real-time. By utilizing various lighting techniques, the system significantly enhances the contrast of the scale lines, thereby minimizing detection errors. A real-time feedback mechanism ensures that nonconforming products are swiftly rejected, maintaining the efficiency of the production line.

Since the system's implementation, the inspection accuracy has surpassed 99.9%, leading to a notable increase in production efficiency and a substantial reduction in waste rates. Furthermore, the system's data recording functionality facilitates quality traceability for the enterprise. This machine vision-based syringe scale inspection system not only elevates product quality but also establishes a solid foundation for the intelligent advancement of the medical device industry.