Label Detection

Detection requirements:

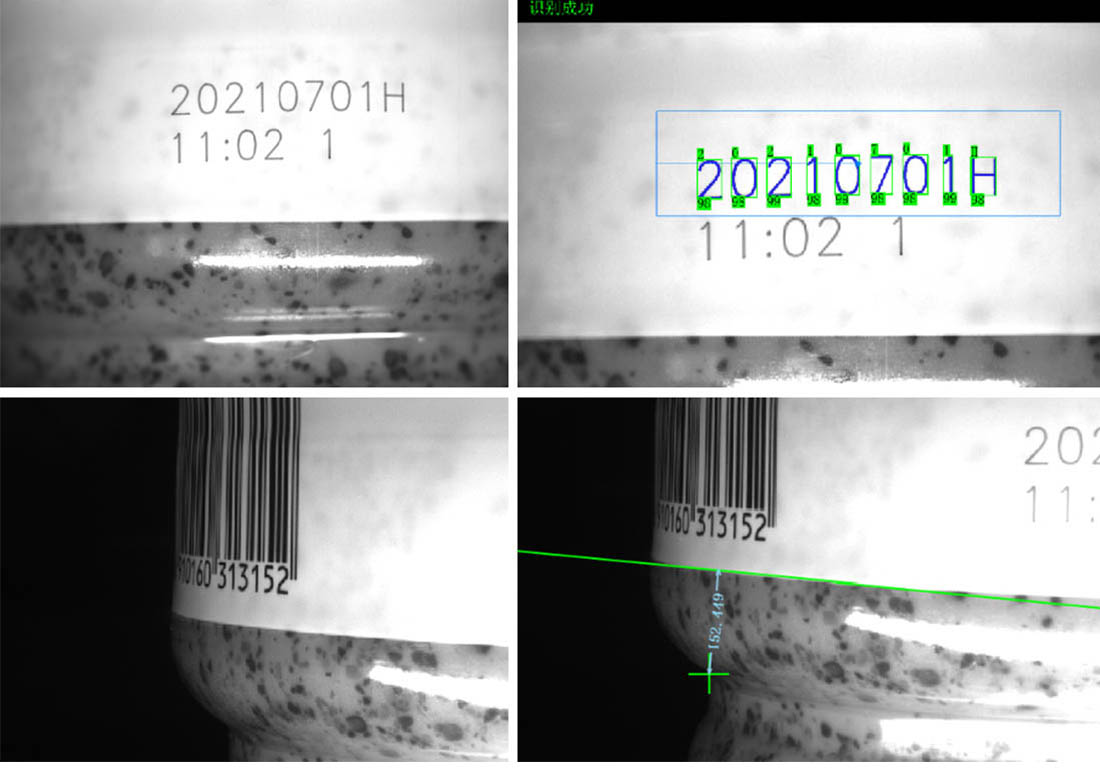

1, date recognition on the label

2, whether the label is offset up and down

3, beat 1pcs/s

Project Details:

In the complex environment of mass production and package printing of labels, labeling equipment is often faced with a variety of challenges such as missed prints, unclear characters and positional shifts. These problems are often triggered by technical and mechanical factors during equipment operation, and if they are not detected and resolved in a timely manner, they may have a direct impact on the print quality and visual effect of the product. Customers may experience unclear label characters or omitted information, which may affect their experience and create a negative impression of the brand image.

Therefore, it is crucial to implement effective quality control during the production process, especially timely and accurate monitoring of label printing quality. To this end, the project introduced an advanced character inspection tool that can accurately identify and record possible printing defects on each label. Meanwhile, a distance tool was used to detect minor deviations of the labels in the top and bottom positions to ensure that each label conforms to the expected positional accuracy and visual effect.

These measures not only help improve productivity and resource utilization, but also significantly enhance the overall quality of the final product and its competitiveness in the marketplace. By ensuring the clarity and integrity of label printing, companies can effectively avoid customer complaints and loss of brand reputation due to quality issues, thus ensuring customer satisfaction and long-term business development.