Detection of PIN Misalignment

Inspection Requirements:

1, The beat is 1pcs/s

Project Details:

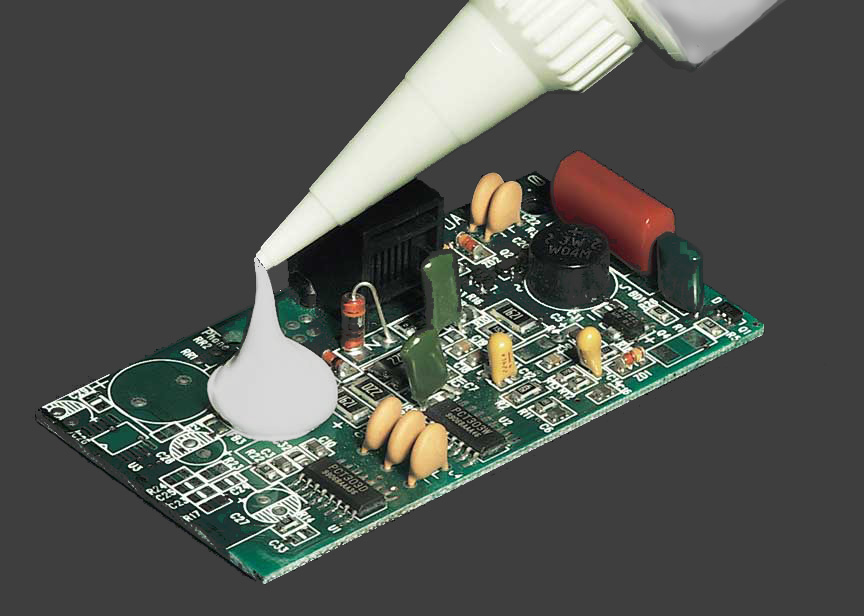

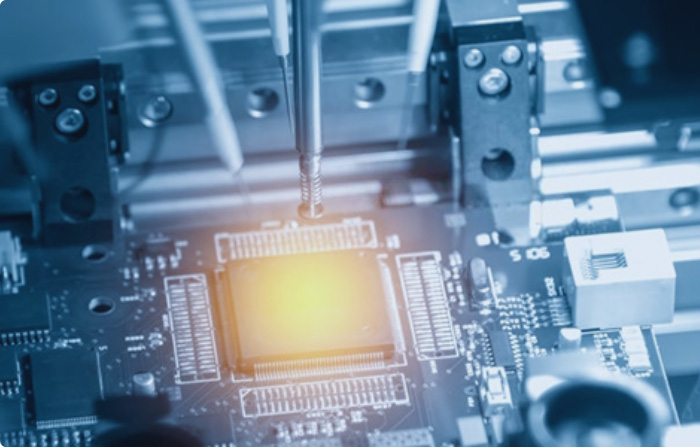

The PIN, a vital metallic component within connectors responsible for the transmission of electrical signals, plays an essential role in the performance and stability of electronic products. Any defects in the PIN, such as poor contact, fractures, or short circuits, can result in the failure of the entire circuit system, adversely affecting product reliability and lifespan. Consequently, ensuring precise inspection of PINs during the manufacturing process has become a crucial task for maintaining product quality.

Currently, machine vision inspection technology has emerged as a significant component of modern industrial intelligence, particularly in the realm of quality control for precision components, where its role continues to grow. To address this need, the PIN vision inspection system harnesses advanced machine vision technology. Equipped with high-resolution industrial cameras and precision optical lenses, alongside Mstar's proprietary image processing algorithms, the system conducts comprehensive real-time inspections of various PIN features. These include the shape, dimensions, accurate positioning, potential misalignment, and any surface defects such as scratches or cracks.

This vision inspection system ensures that each PIN undergoes thorough quality assessment through high-precision image capture and processing, significantly enhancing inspection efficiency while markedly reducing errors and omissions often associated with manual inspections. Furthermore, through its automated detection process, the system swiftly identifies non-conforming PINs on the production line, effectively preventing defective products from entering the market and safeguarding both overall product performance and user experience.