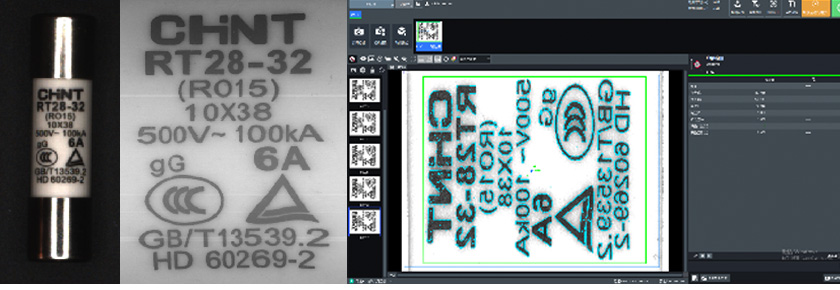

Fuse Printing Inspection

Inspection Requirements:

1, The beat is 1 pcs/20s

2, Speed: 15 m/min

Project Details:

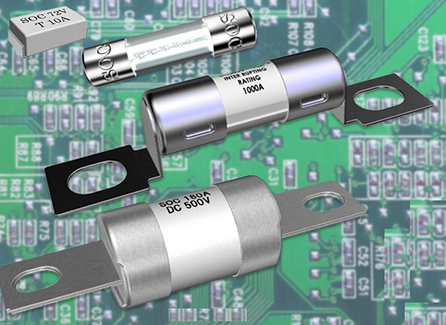

In the electrical manufacturing industry, fuses serve as critical components for circuit protection, and the printed information on their surfaces (such as model numbers and specifications) is vital for product identification and quality traceability. However, traditional manual inspection methods are susceptible to human error, leading to inefficiencies and a high rate of misjudgments. To address these challenges, a certain electrical enterprise has implemented machine vision technology to achieve intelligent and automated inspection of printed information.

The system captures images using high-resolution industrial cameras and employs OCR recognition and edge detection algorithms to conduct real-time assessments of the integrity, clarity, and positional accuracy of the printed content. Inspection results are rapidly compared against standard templates to identify defective products, integrating seamlessly with the Manufacturing Execution System (MES) for comprehensive data tracking throughout the process.

With the introduction of machine vision, the accuracy of inspections has soared to 99.8%, production efficiency has increased by 10%, and the rate of defective products has halved. Compared to manual methods, this intelligent solution not only enhances inspection quality but also reduces rework and recall costs. Furthermore, the system demonstrates excellent adaptability, capable of accommodating variations in ambient lighting and the complexities of diverse printed fonts.