Seal Integrity Inspection of Plastic Films

Detection requirements:

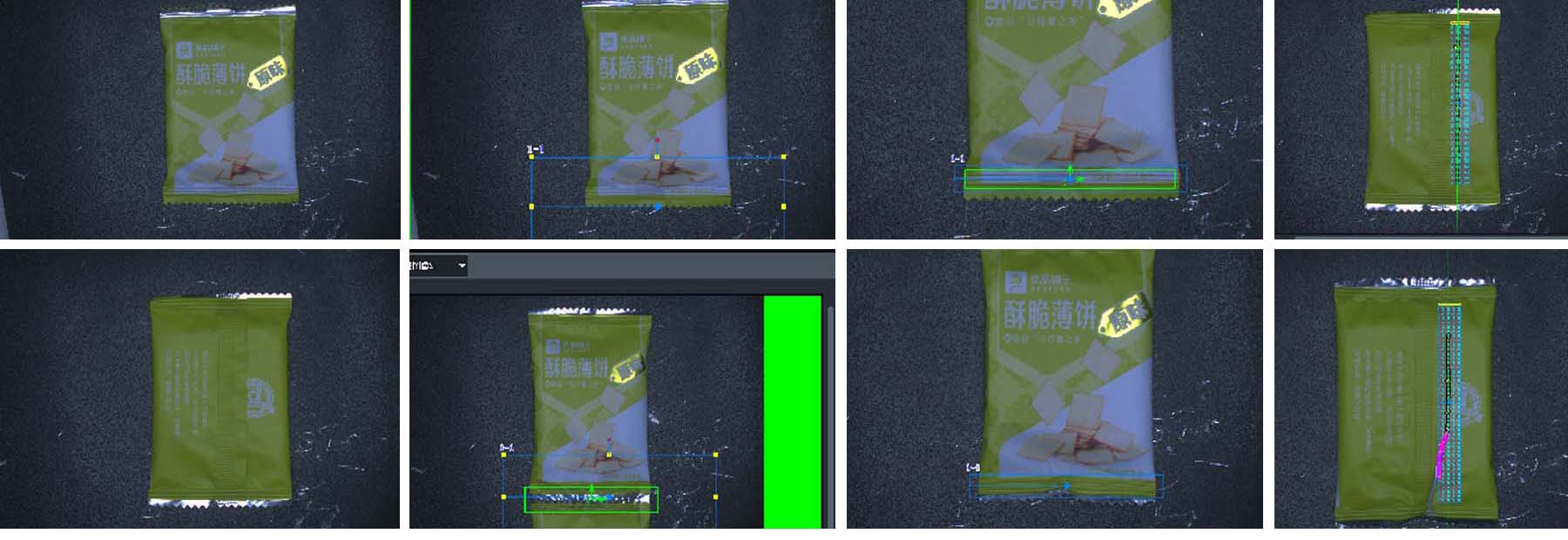

1, Detection of plastic film misalignment and deformation

2, Inspection of overall appearance. Detection of connected packages. Dynamic imaging

3, The beat is 4.25 PCS/S

Project Overview:

Seal integrity inspection is a critical quality control process in product manufacturing, directly impacting product shelf life and consumer satisfaction. Traditionally, this task has been performed manually, leading to inconsistent results, low efficiency, and high labor costs. Advances in machine vision technology offer a promising solution to these challenges.

This project aims to replace manual inspection with an automated machine vision system to significantly enhance the quality and efficiency of seal integrity inspection. Specifically, we will employ contour detection algorithms to precisely locate the package, ensuring accurate and consistent inspection. By leveraging advanced AI techniques, the system will automatically identify seal integrity and package connectivity issues, promptly flagging any defects.

The detection of seal integrity is paramount to product quality. Compromised seals can lead to product contamination, degradation, and a diminished consumer experience. Package connectivity issues can affect product individuality and packaging integrity, causing complications in logistics and sales. Through AI-powered defect detection, we can efficiently and accurately identify these issues, mitigating the risks associated with manual inspection.