Machine vision inspection has become an indispensable tool in the packaging industry. It enhances production efficiency, improves product quality, and reduces errors and costs associated with manual operations. This article explores the applications of machine vision inspection in packaging and its advantages in modern production lines.

Machine Vision Inspection: The Latest Advancement in Automated Quality Control

Machine vision inspection utilizes cameras and image processing software to capture, process, and analyze images of packaged products, enabling automated inspection and sorting. High-precision cameras and advanced image processing software allow for detailed examination of products to detect defects or irregularities.

Applications of Machine Vision Inspection in the Packaging Industry

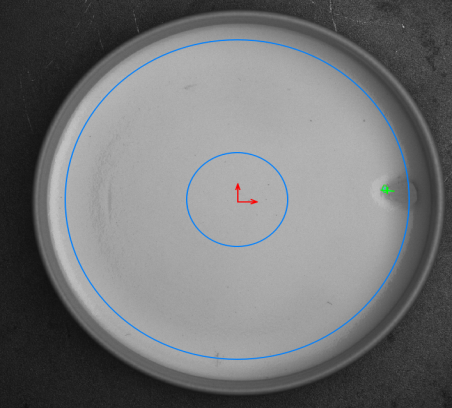

Packaging Integrity Inspection

Machine vision systems capture images of packaging and use image processing techniques to identify defects such as cracks, damage, or improper sealing. This ensures that the packaging provides adequate protection for the product inside. Automating this process significantly reduces the time and cost of manual inspection while enhancing accuracy and efficiency.

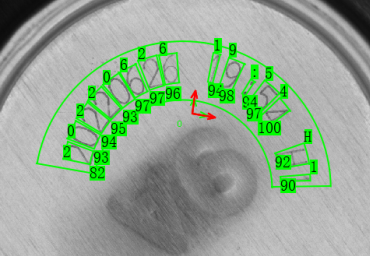

Label, Barcode, and QR Code Verification

Machine vision systems can swiftly and accurately read barcodes and QR codes, aiding businesses in product tracking and improving logistics management efficiency. Additionally, they verify whether labels are correctly positioned and ensure that printed text and images are clear and complete. These capabilities enhance overall operational efficiency and management precision.

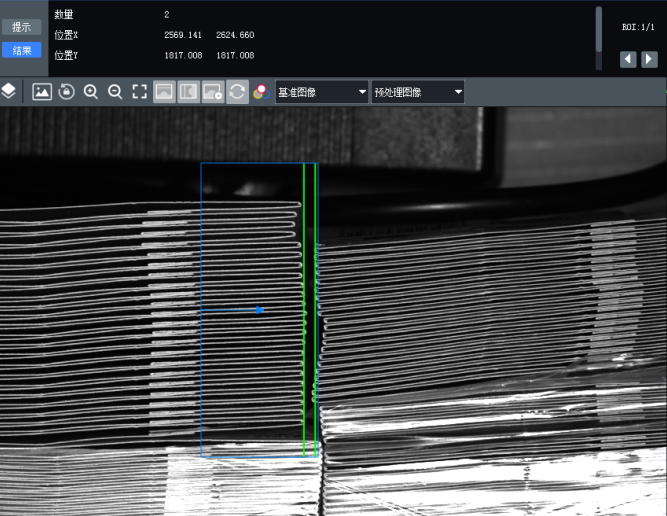

Size and Shape Inspection

Machine vision systems assess whether the dimensions and shapes of packaging meet specified requirements, ensuring safe storage and transportation. They can also inspect printed text and images for clarity, completeness, and color accuracy, thereby upholding product quality and brand image.

Advantages of Machine Vision Inspection

Enhanced Efficiency

Machine vision inspection operates 24/7 without fatigue, eliminating human errors and significantly boosting inspection efficiency.High Precision

Utilizing high-resolution cameras and advanced image processing algorithms, machine vision detects minute defects that may be overlooked by the human eye, ensuring superior product quality.Cost Savings

By reducing reliance on manual labor, machine vision inspection lowers operational costs and minimizes losses caused by human errors.High Reliability

Machine vision-based decisions rely on precise image analysis rather than subjective human judgment, providing greater consistency and reliability.

Conclusion

As technology continues to evolve, machine vision inspection is becoming increasingly integral to the packaging industry. It not only enhances production efficiency and product quality but also reduces operational costs and human errors. Looking ahead, machine vision inspection is expected to expand into more sectors, bringing greater convenience and benefits to manufacturing and daily life.

MSTAR TECHNOLOGIES’ intelligent machine vision software, HCvisionQuick, offers functions such as positioning, inspection, measurement, and identification. In automated production, it facilitates tasks including object positioning, quality defect detection, dimensional measurement, component counting, recognition confirmation, and alignment assembly. Integrated with high-performance vision processors, cameras, lighting, lenses, and accessories, MSTAR TECHNOLOGIES provides high-precision, highly stable machine vision solutions tailored to client needs.

If you are facing challenges in visual inspection for packaged products, MSTAR TECHNOLOGIES is ready to be your trusted partner. With extensive experience and cutting-edge technology, we offer comprehensive machine vision solutions to address quality control challenges in your production processes.