Exploring Applications of Robotic Vision-Guided Technology

Robotic vision-guided technology has emerged as a cutting-edge solution in automation, permeating various industries and revolutionizing production processes by enhancing efficiency, precision, and flexibility. Below is a closer look at its applications across different scenarios:

1. Automotive Component Assembly

Features:

In assembly lines for engines, transmissions, and car bodies, vision-guided robots identify complex part features, ensure precise positioning, and perform assembly tasks. For instance, robots can detect cylinder block features to install pistons and connecting rods, maintaining strict clearance control and assembly sequences. Additionally, the vision system monitors parameters like valve gaps and bearing preload in real time to ensure quality.

Benefits:

- Improved assembly accuracy and efficiency

- Reduced human errors

- Enhanced production throughput and minimized rework rates

2. Logistics Sorting Centers

Features:

Vision-guided robots in sorting centers rapidly recognize barcodes, QR codes, labels, or package dimensions to determine proper destinations or conveyor routes. By leveraging deep learning algorithms, they can handle irregularly shaped parcels for accurate picking and sorting.

Benefits:

- Faster and more accurate sorting

- Reduced labor costs

- Optimized warehouse space utilization

- Increased logistics turnover efficiency

3. Electronics Manufacturing

Features:

In PCB assembly, component placement, and precision soldering, vision-guided robots identify tiny pads, component polarity, and pin shapes for accurate IC chip, resistor, and capacitor placements. The system also inspects solder quality to ensure high manufacturing standards.

Benefits:

- Avoids quality issues like shorts or cold solder joints

- Increases production yield

- Supports miniaturization and complexity in electronic products

4. Medical Equipment Assembly

Features:

In cleanroom environments, vision-guided robots assemble intricate components of medical devices, such as endoscopes and surgical robots, with high precision. Integrated force sensing ensures appropriate assembly force to maintain device performance without over-tightening or loosening.

Benefits:

- Enhanced product reliability

- Compliance with strict medical standards

- Accelerated product development and market launch

- Reduced contamination risks

5. Food Packaging Lines

Features:

Robots equipped with vision systems recognize food shapes, sizes, and positions to adjust their picking strategies for precise handling and placement, minimizing damage. They also perform weight checks and inspect for visual defects to ensure packaging quality.

Benefits:

- Improved packaging efficiency and consistency

- Reduced food waste

- Enhanced customer satisfaction

- Compliance with stringent food safety regulations

6. Aerospace Manufacturing

Features:

In the production of aircraft and rockets, vision-guided heavy-duty robots identify docking holes and edge contours for precise alignment and welding of large components. They also support high-precision tasks like composite material placement and laser cutting.

Benefits:

- Ensures structural integrity and airtightness

- Reduces manufacturing errors

- Shortens production cycles

- Enhances product quality and safety

7. Semiconductor Wafer Handling

Features:

In cleanrooms, vision-guided robotic arms identify wafer positions, edges, and markings for damage-free handling, precise alignment, and transfer. Integrated defect detection removes non-conforming wafers, ensuring smooth semiconductor production.

Benefits:

- Higher wafer processing yield

- Lower production costs

- Accelerated technological iteration

- Advancement in integrated circuit manufacturing

8. 3C Product Assembly

Features:

Vision-guided robots meet the demands of diversified, small-batch production in assembling smartphones, laptops, and other consumer electronics. They accurately position and assemble components like screens, buttons, and cameras.

Benefits:

- Enhanced assembly flexibility and efficiency

- Adaptability to market changes

- Shortened time-to-market

- Improved product quality and consistency

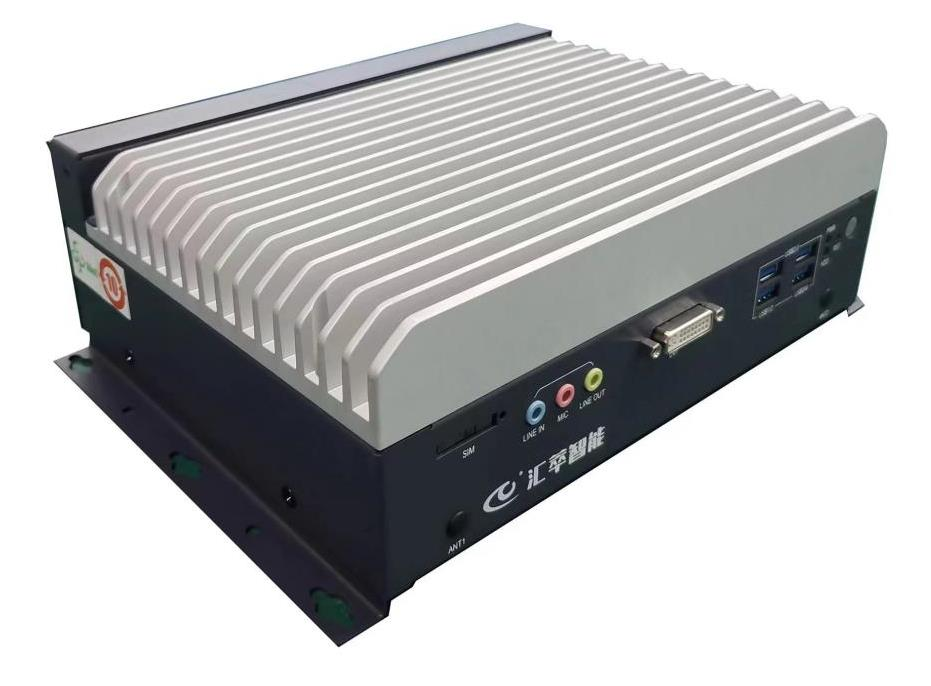

Excellence in Vision-Guided Robotic Systems

With broad compatibility, user-friendly interfaces, high precision, and automated calibration, robotic vision-guided systems from MSTAR TECHNOLOGIES provide plug-and-play solutions for diverse industries. Thousands of enterprises have leveraged these systems to enhance the flexibility, stability, and accuracy of their automated production lines.

From automotive components to logistics, electronics, medical devices, food packaging, aerospace, semiconductors, and 3C products, robotic vision-guided technology plays a pivotal role in advancing intelligent production. By boosting operational precision, efficiency, and quality, this technology delivers significant economic and competitive advantages to modern businesses.