What is Visual Color Difference Detection?

Visual color difference detection is a method that uses machine vision technology to assess color discrepancies. By processing and analyzing images, this method can identify color variations on the surface of objects or products. The goal is to ensure that the color of a product meets predefined standards, which is particularly important in industries such as manufacturing, textiles, and automotive, where color consistency is key to product quality.

what are the main types of products used for visual color difference detection?

Types of Visual Color Difference Detection Products

Currently, there are several categories of visual color difference detection products available on the market. These can be classified as follows:

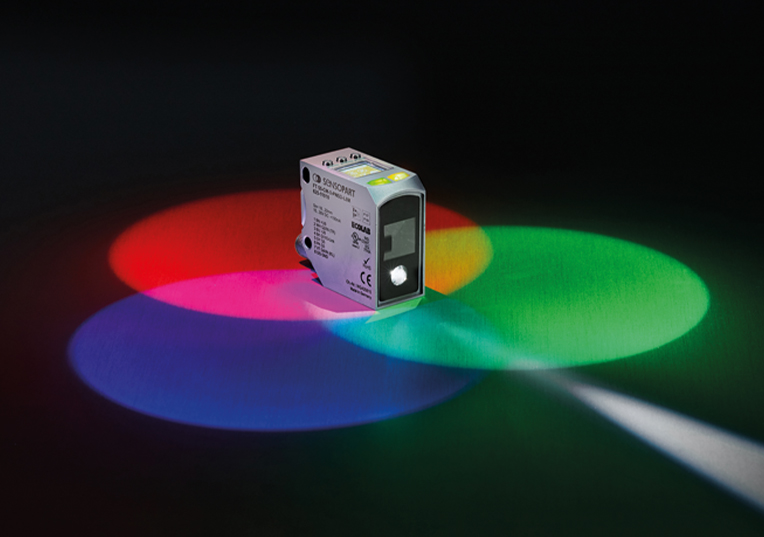

1. Color Difference Meters

A color difference meter is a device specifically designed to measure and analyze color variations between objects. It works by comparing the test object's color with a reference standard to determine if a color difference exists. Typically, the device uses a light source to illuminate the object being tested, and it employs color sensors or cameras to capture image data. Advanced algorithms then analyze the color differences. Color difference meters are widely used in industries that require precise color matching, such as plastics, coatings, and textiles.

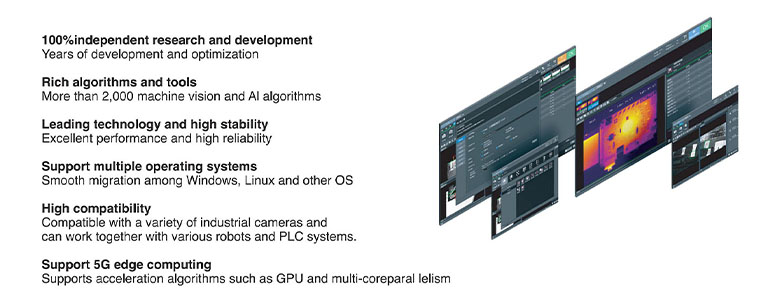

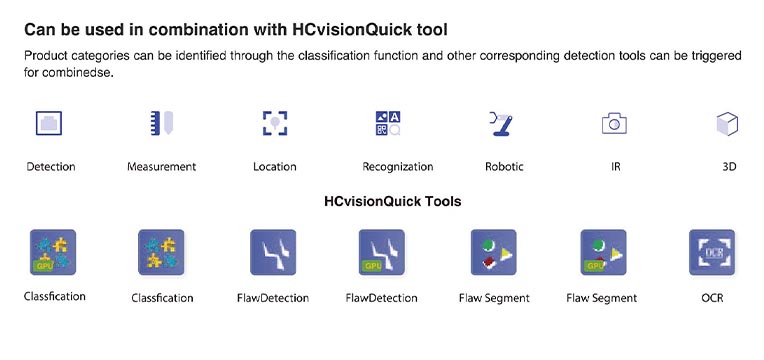

2. Intelligent Vision Systems

Intelligent vision systems are commonly used in automated production lines to detect color differences between a product under inspection and a standard sample. These systems can quickly determine if a color mismatch is present, with the ability to identify and classify the color differences. The results are usually displayed visually, and some systems include alarm functions for immediate detection. Well-known international brands in the market include Cognex and Keyence, while domestic leaders, such as MSTAR TECHNOLOGIES General High-Speed Machine Vision Systems, offer customized vision detection solutions tailored to specific customer needs.

3. Handheld Color Meters

Handheld color meters are portable devices designed to measure color differences by scanning or touching the surface of an object. These instruments are typically lightweight, easy to use, and come with simple interfaces and display screens. They are ideal for on-site testing and real-time decision-making. While they can deliver immediate data, these devices do not connect to computers and lack sophisticated software integration. They are typically used in industries such as plastics for color measurement and matching, but their accuracy is generally lower compared to more advanced systems.

4. Software Applications

Several software applications are available for visual color difference detection. These programs can run on computers or mobile devices and rely on image processing and analysis algorithms to detect and assess color differences. Many of these applications are user-friendly, offering intuitive interfaces and features such as data management and reporting tools. These software solutions are often used for batch processing, high-throughput testing, or integration into larger automated systems.

Choosing the Right Visual Color Difference Detection Product

When selecting a visual color difference detection product, it's important to consider factors such as the specific application, required precision, and budget. Some manufacturers offer customized solutions that can be tailored to meet the unique needs of individual customers. Whether you need a simple handheld meter for basic field testing or a sophisticated intelligent vision system for automated production environments, there are many options available to suit various industries and use cases.

In conclusion, the growing demand for color consistency in various industries makes visual color difference detection a crucial part of quality control. By choosing the right product for the job, businesses can ensure that their products meet color standards, enhance customer satisfaction, and maintain the integrity of their brand.