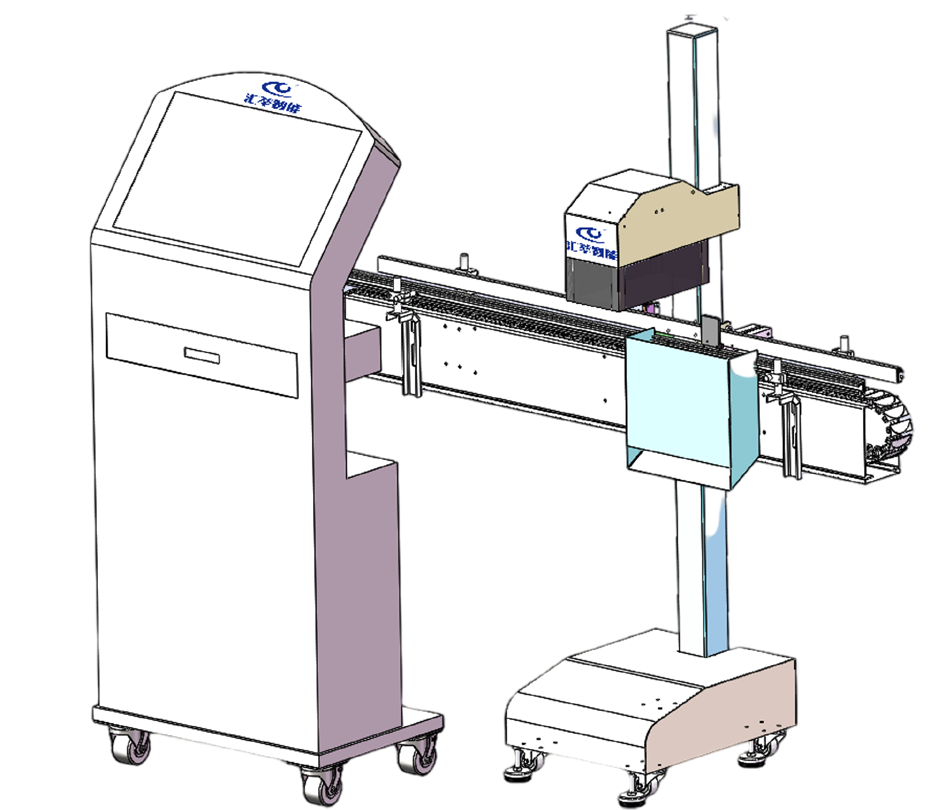

Aluminum Foil Heat Seal Testing Equipment

HC-Rfinfrared-v6.0

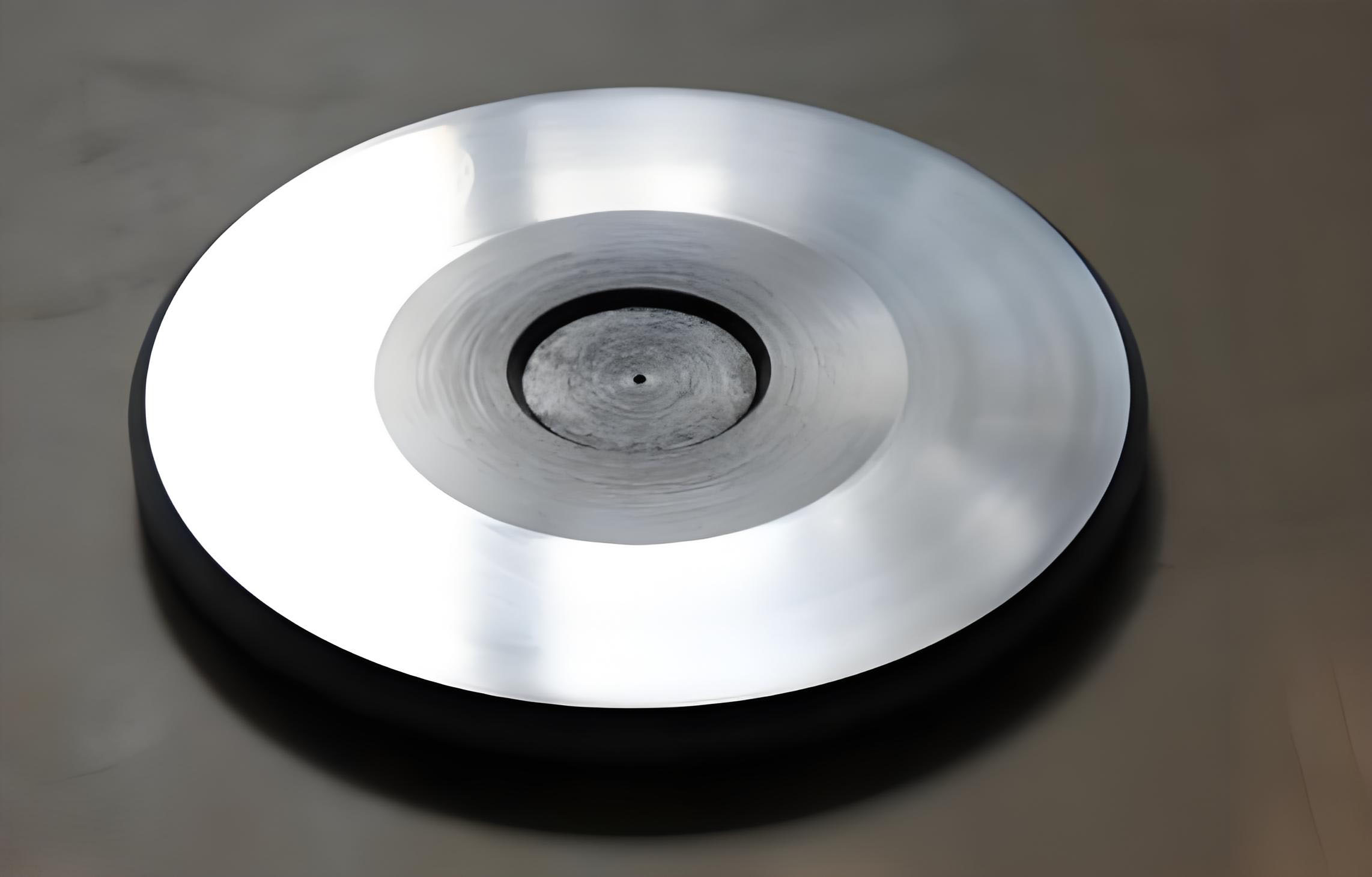

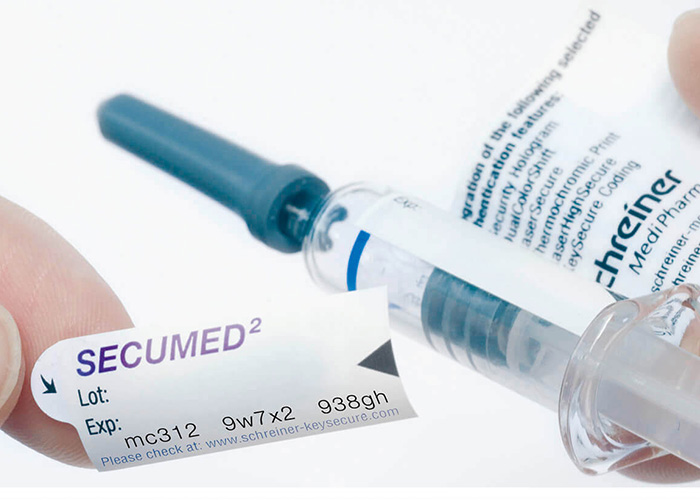

The Aluminum Foil Heat Seal Testing Equipment is an automated system that uses an infrared camera to inspect the heat seal quality of products on the production line. Defective products with incomplete seals are automatically removed and directed to a recycling bin. The system includes a housing, visual inspection mechanism, and an encoder-driven removal system. As products pass through, a sensor triggers the camera to detect seal defects, and faulty items are discarded accordingly.

Versatility

Compatible with a wide range of products, including those with complex shapes and materials.

Ease of Use

User-friendly interface for simple operation and maintenance.

High-Speed Inspection

Inspection speed can reach up to 360 pieces per minute or more, depending on the product size and specifications.

Customization

Offers customizable features to meet specific customer requirements.

Autonomous Operation

The machine can start and operate independently, reducing manual intervention.

Model

HC-Rfinfrared-v6.0

Operating Voltage

AC220V ±10% 50Hz

Equipment Power

2.0KW

Air Pressure

0.4-0.6MPa

Operating Temperature

0 ~ +50°C

Environmental Humidity

20% ~ 80% RH

External Dimensions

700*700*1800 (LWH) mm

Machine Weight

130kg

Installation Position

Within 0.4-2m after the sealing machine