Background

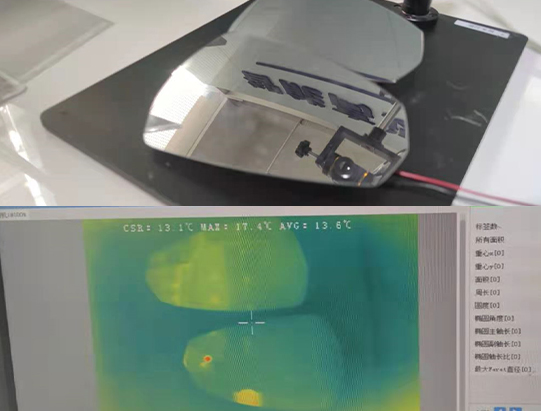

Rear windshield heater wires are essential for defogging and defrosting during the autumn, winter, and rainy seasons, becoming a standard feature in every vehicle. Typically, these heater wires are printed on the inner surface of the glass using conductive resistive printed lines. The process is simple, thin, and does not affect visibility. However, if there are issues with the heater wires or uneven heating, it may affect the defogging and defrosting performance, and in severe cases, could even lead to the glass breaking. By using infrared thermal imaging, the temperature of the heater wires can be visually displayed, helping to promptly identify high-temperature points caused by broken or poorly connected wires, ensuring product quality

Solution

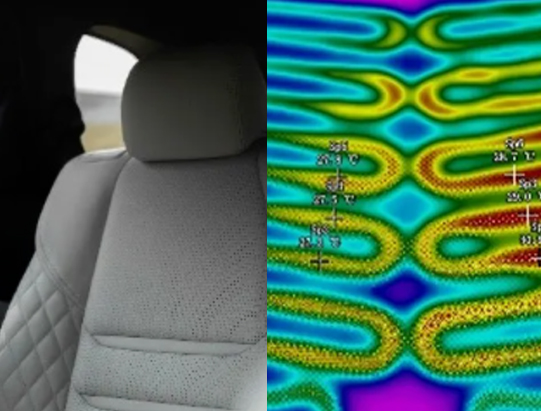

The thermal imaging camera provides an efficient optimization solution for temperature, power, and wire breakage detection. By dynamically monitoring the temperature of the glass, the thermal camera ensures even heating of the wires, quickly locates abnormal areas, and adjusts the layout accordingly. It also allows for real-time adjustments to silver paste formulation, printing thickness, and tempering processes to avoid overheating or overcooling, improving product consistency. In terms of power optimization, the thermal camera records the heating curve, evaluates whether the heater wire’s power meets the required standards, and conducts long-term monitoring to assess power stability and durability. For wire breakage issues, the thermal camera precisely locates low-temperature areas and integrates into the production line for online detection, automatically outputting inspection results to improve testing efficiency.

Benefits

- Non-Contact Temperature Measurement: The infrared thermal imaging camera can measure the surface temperature in real time without touching the glass, preventing interference with the glass and heater wires caused by traditional contact-based temperature measurements.

- Comprehensive Temperature Distribution Imaging: The thermal camera quickly captures the entire temperature distribution across the glass surface, detecting not only individual point temperatures but also accurately locating abnormal areas of the heater wires.

- Efficient and Precise Detection: With high resolution and precise temperature measurement capabilities, the thermal camera can complete quality inspections of large quantities of glass in a short amount of time, greatly enhancing production efficiency and testing accuracy.