Background

In the automotive manufacturing process, the heat treatment and high-speed rotation testing of brake pads are crucial. Their quality directly affects the effectiveness and reliability of the vehicle during parking or emergency braking, which is essential for the safety of both drivers and passengers. Using infrared thermal imaging cameras, the temperature change process of the brake pads after operation can be comprehensively monitored, providing detailed temperature distribution data to assess their braking performance and wear resistance, ensuring the stability and safety of the braking system.

Solution

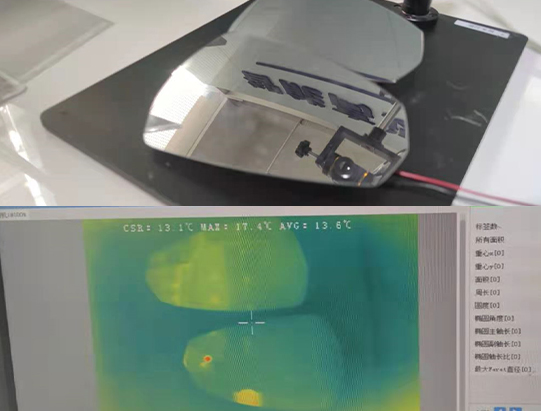

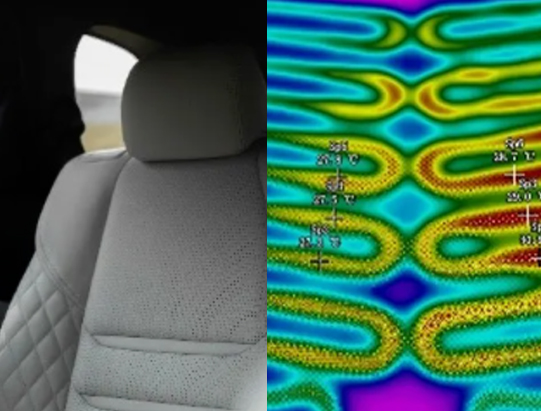

The infrared thermal imaging-based solution can be used for braking performance testing, wear resistance evaluation, and dynamic condition simulation. During braking performance testing, the thermal camera records the temperature change trends of the brake pads, analyzing how braking force changes with temperature, thereby optimizing the friction material formula. In wear resistance evaluation, multiple brake tests monitor the uniformity of temperature distribution, accurately locating hot spots and analyzing wear characteristics to improve the match between the brake pads and brake discs. In dynamic condition simulation, the thermal camera simulates emergency braking under different vehicle speeds and load conditions, recording maximum temperature and cooling rates, providing reliable reference data for actual conditions.

Benefits

- Comprehensive Temperature Distribution Imaging: Compared to traditional contact-based thermocouples and infrared point thermometers, thermal imaging cameras can present the overall temperature distribution of the brake pads in real time, providing more intuitive and comprehensive data support to ensure the accuracy and completeness of the measurement results.

- Efficient Non-Contact Temperature Measurement: The thermal imaging camera uses a non-contact measurement method, which does not affect the working state of the brake pads, especially in high-speed dynamic testing scenarios. Its easy operation and quick response significantly improve testing efficiency and accuracy.

- Precise Analysis and Fault Diagnosis: Through high-resolution thermal images, the thermal camera can accurately identify temperature anomalies, helping engineers quickly pinpoint potential issues, optimize brake pad design, and improve product performance and safety.