Background

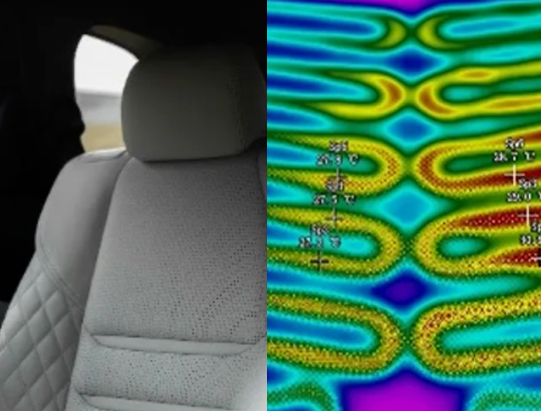

The comfort and safety of heated car seats are highly dependent on their temperature uniformity. If the heating elements in the seats have uneven temperature distribution, local overheating, or abnormally low-temperature areas, it can not only affect the user experience but also pose safety risks. Therefore, it is crucial to conduct strict temperature uniformity testing during the production process.

Solution

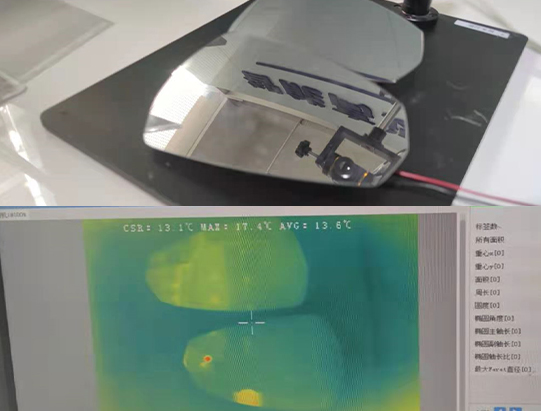

By utilizing thermal cameras, the temperature distribution and heating trends can be visually and conveniently observed when the heating elements are operational. This ensures that the heating method design is optimized for safer and more comfortable user experience. Additionally, thermal cameras can help detect defects in electric heating devices that could potentially lead to overheating of components, causing fire hazards in the seats.

Benefits

- Comprehensive Detection: Thermal images display the overall temperature distribution of the seat, making it easy to identify local temperature anomalies such as hotspots, cold spots, or uneven areas.

- Fast Detection: Thermal cameras can complete a full temperature scan of the heated seat in just a few seconds, greatly improving detection speed compared to point-by-point methods.