Background

Tire quality is directly related to driving safety, and its material performance is affected by temperature. Excessive heat can cause performance degradation and accelerate wear. The surface temperature of the tire determines its grip and tire pressure, making it an important parameter for assessing its working condition. Infrared thermal imaging can monitor temperature distribution in real-time, providing an intuitive evaluation of tire performance. During design and production, engineers can optimize material selection to improve durability; during automotive R&D, it can also be used to test tire and vehicle compatibility, ensuring safety and reliability.

Solution

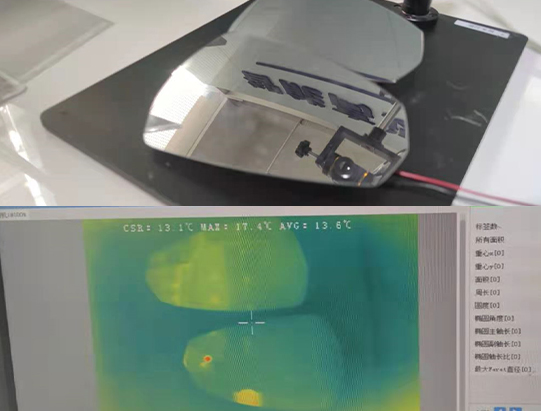

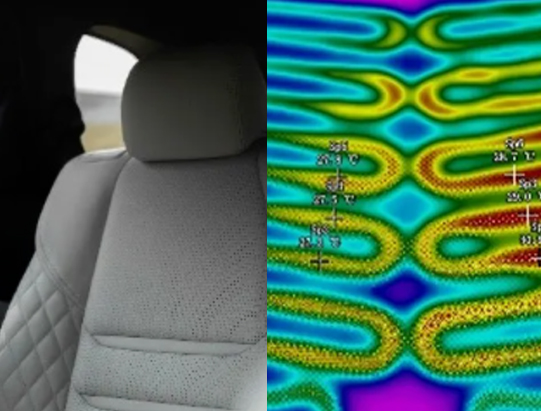

In optimizing tire temperature distribution, the thermal imaging camera can be used to record temperature distribution on tires under different speeds and load conditions, precisely locating hot spots on the surface and analyzing whether there are design flaws or material issues. Additionally, it can monitor the heat generated from the tire's friction with the road surface, providing data to optimize tread materials and improve wear resistance and heat dissipation performance. In tire durability testing, the thermal imaging camera can conduct long-term dynamic monitoring under simulated real-world conditions, recording temperature changes on the tire surface and analyzing whether the temperature rise curve meets design requirements. Furthermore, by capturing temperature hotspots and distribution anomalies, potential fatigue damage areas can be predicted in advance, providing a scientific basis for improving tire reliability.

Benefits

- Real-Time Dynamic Monitoring: The infrared thermal imaging camera can capture 30 frames of high-frequency thermal imaging data per second. Even at high speeds of 100 km/h, it can accurately capture the temperature distribution on the tire surface. This feature allows engineers to thoroughly analyze thermal changes in tires under high-speed operating conditions.

- Non-Contact Temperature Measurement: Compared to traditional contact-based temperature measurement methods, the infrared thermal imaging camera does not need to directly contact the tire, ensuring no impact on its performance or structure. It is especially suitable for dynamic testing scenarios involving high-speed rotation, ensuring a safe and efficient measurement process.

- High-Resolution Temperature Imaging: The infrared thermal imaging camera generates clear temperature distribution maps, visually displaying temperature differences, hot spots, and uniformity on the tire surface, providing precise, visual data support for R&D and optimization.