Background

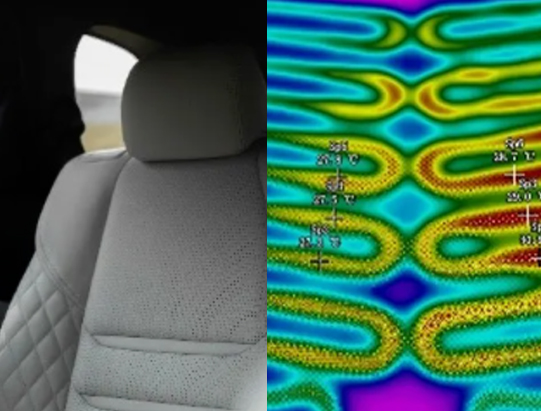

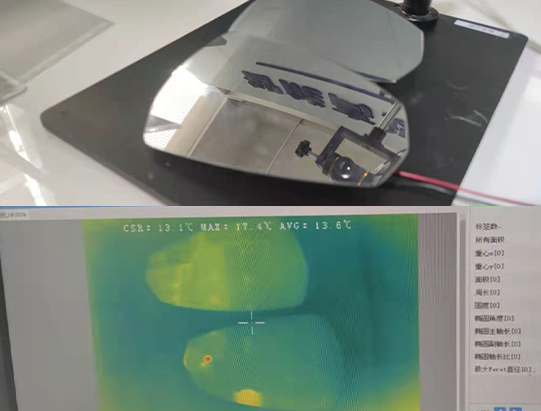

The heating function of car side mirrors is critical for driving safety in winter and humid environments, as it effectively prevents fogging and frosting, ensuring clear visibility. However, during production and quality control, it is necessary to test the functionality of the heating elements to ensure they work properly. Traditional inspection methods often have low efficiency and limited precision, making them inadequate for large-scale production needs.

Solution

Using long-wave infrared thermal imaging technology, the temperature distribution of the heated elements in the side mirrors can be monitored in real-time after they are powered on. This method provides a non-contact, efficient, and intuitive way to inspect the functionality of the heating elements, ensuring product quality and optimizing production processes.

Benefits

- Enhanced Detection Accuracy: Infrared thermal imaging technology allows precise measurement of the temperature distribution on the mirror surface, detecting minute temperature differences. It can promptly identify issues with the heating element, such as localized overheating or uneven heating.

- Increased Production Efficiency: The speed of infrared thermal imaging inspection is fast, enabling rapid testing of side mirrors on the production line. This enhances production efficiency, meeting the demands of large-scale manufacturing.