Background

The automotive industry has seen steady development in recent years, with a growing variety of door types in production. Traditionally, adhesive application for all door types has relied on manual operations, resulting in inconsistent quality, excessive waste, and inefficiencies. By leveraging industrial robots and 3D vision technology, the automation of door frame adhesive application can effectively address the challenges of handling diverse door types, improve adhesive quality, and boost production efficiency.

Solution

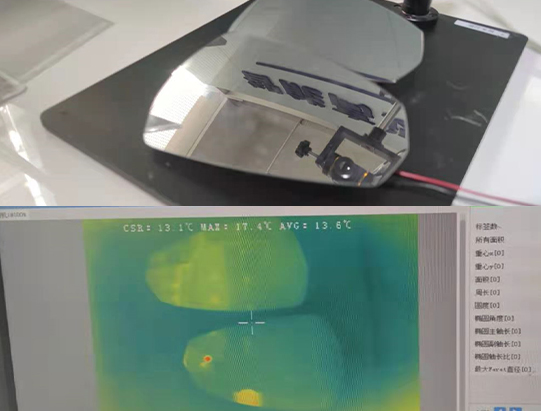

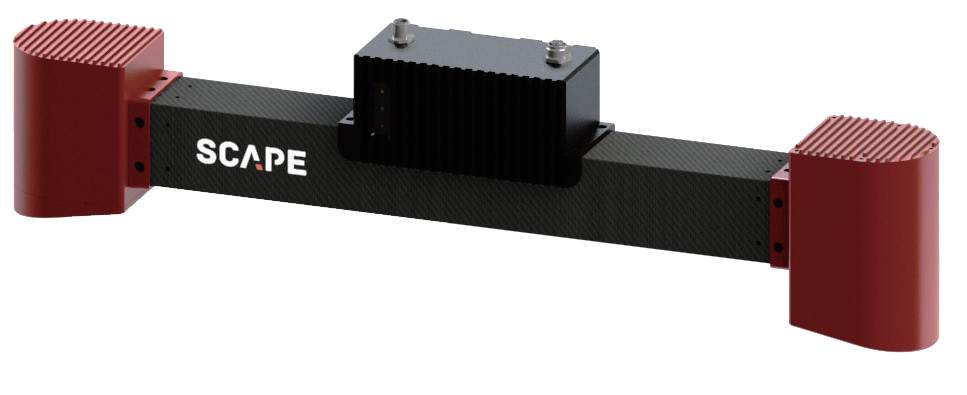

A 3D camera is used to capture the product's point cloud data, accurately identifying the position of the door frames. The system matches the identification results with pre-defined trajectory templates. The vision system then sends the adhesive application trajectory to the robot, guiding it to perform the operation along the precise path. This ensures accurate adhesive placement, enhances production efficiency, and reduces human error.