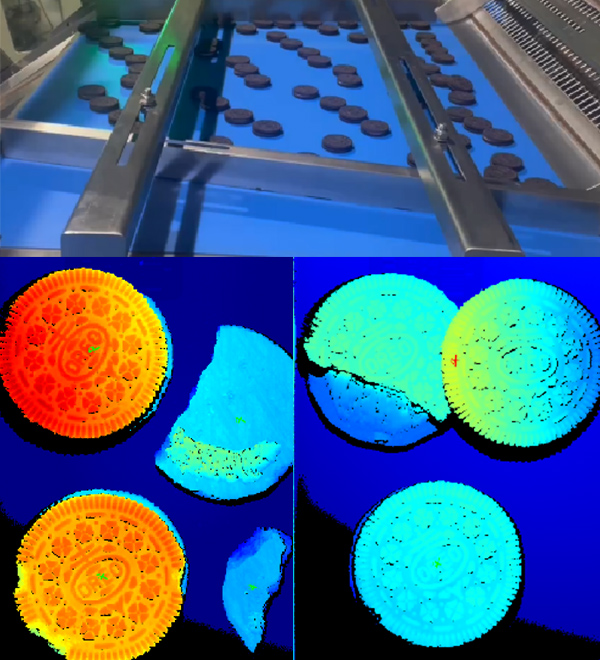

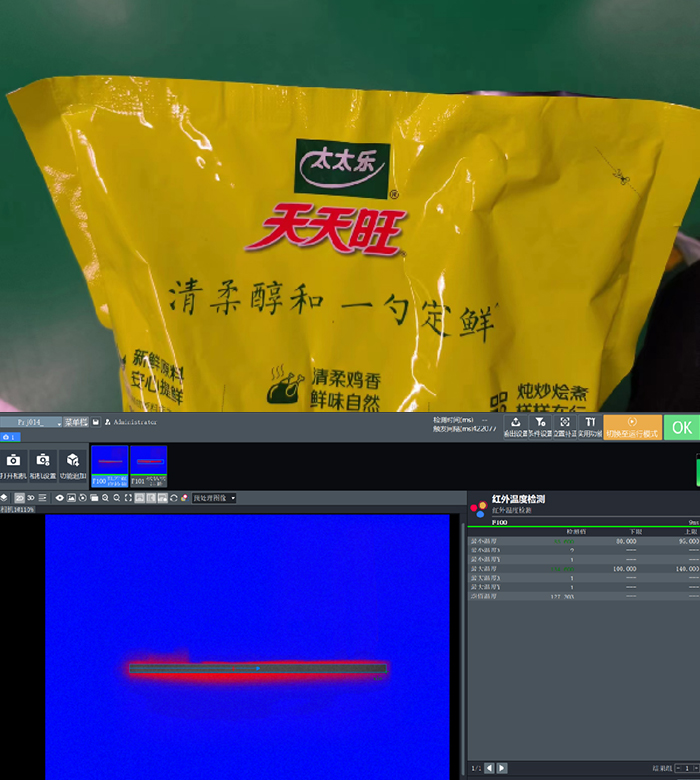

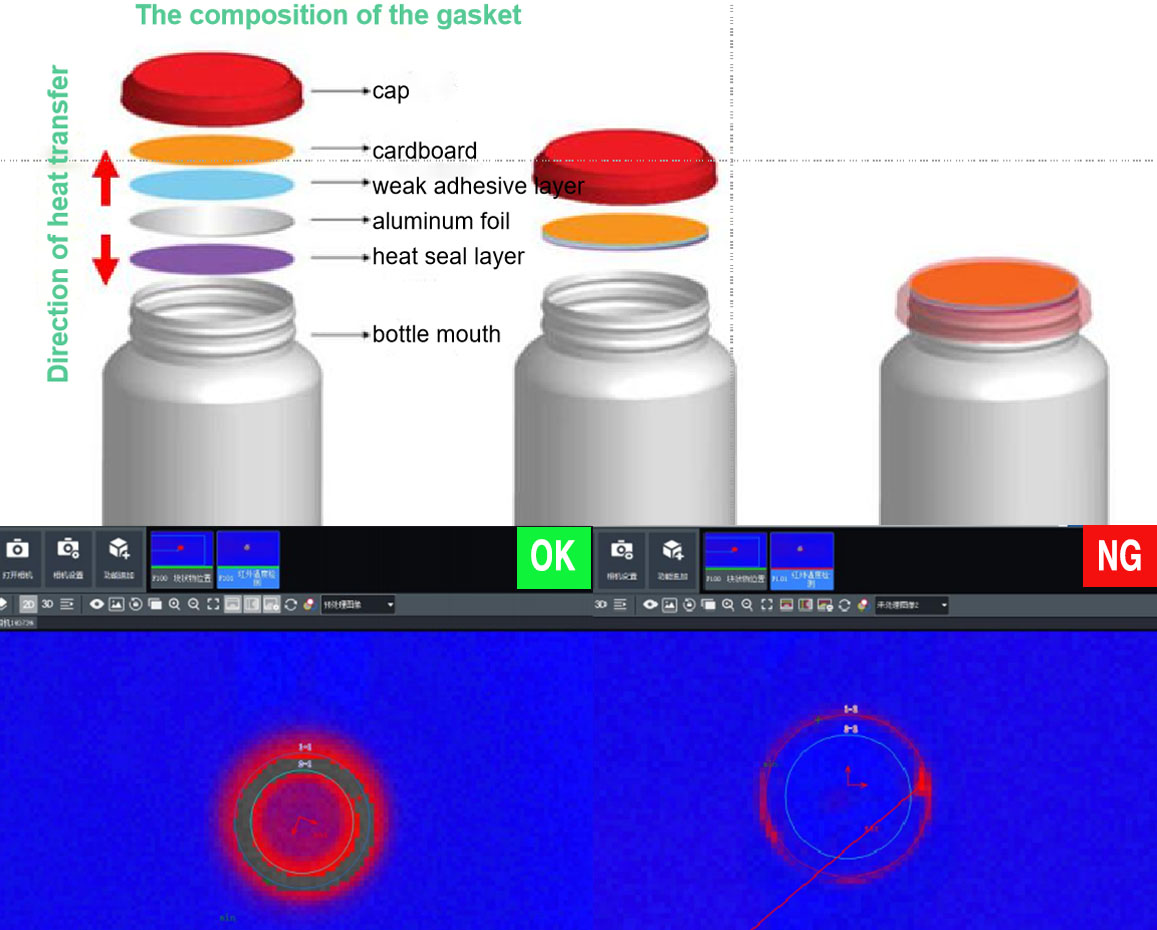

Infrared temperature measurement and thermal imaging are used to locate undercooked food and pause the production line to remove the undercooked items.

Background

The application of infrared thermal imaging technology in flatbread production addresses the strict requirements of the food industry for quality, safety, and efficiency. With consumers' increasing focus on food quality and regulatory standards, businesses must ensure consistent cooking, moisture levels, and uniformity, while avoiding undercooking or overbaking. Large-scale production demands real-time, efficient inspection technologies to reduce waste and optimize costs, and traditional methods are insufficient to meet the needs for automation and intelligence.

Solution

Mstar infrared thermal imaging uses temperature measurements to locate undercooked food on the production line. This application not only meets the high-quality and efficiency demands of flatbread production but also provides an innovative solution for the intelligent development of the food industry.

Benefits

Non-Contact: Infrared thermal cameras detect temperature without touching the flatbread, preventing contamination or interference, making it ideal for real-time monitoring in high-temperature environments.

Real-Time Feedback: Rapidly captures temperature changes in the flatbread, providing immediate data for process adjustments and improving production efficiency.

Precise Control: Temperature data analysis helps optimize oven temperature curves and conveyor belt speed, ensuring consistent quality in each batch of flatbread.