Background

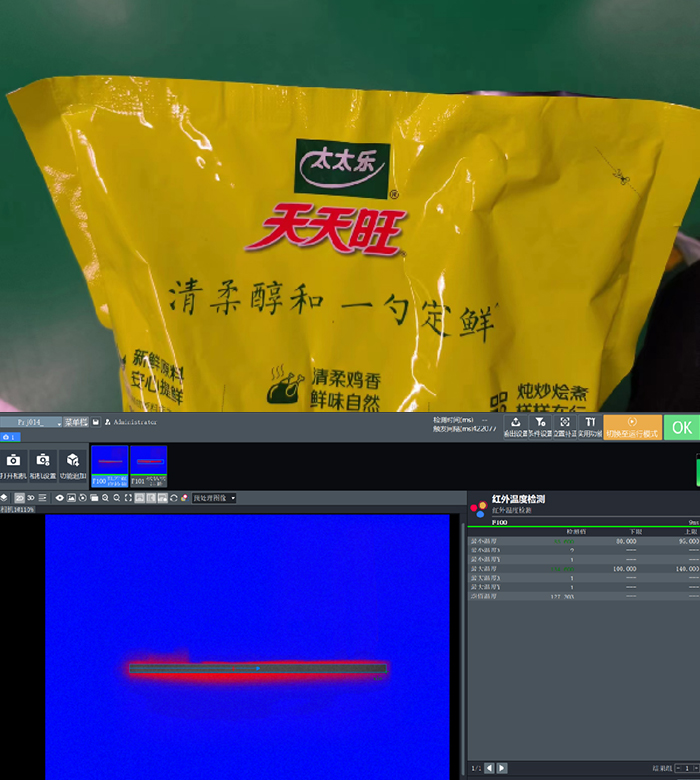

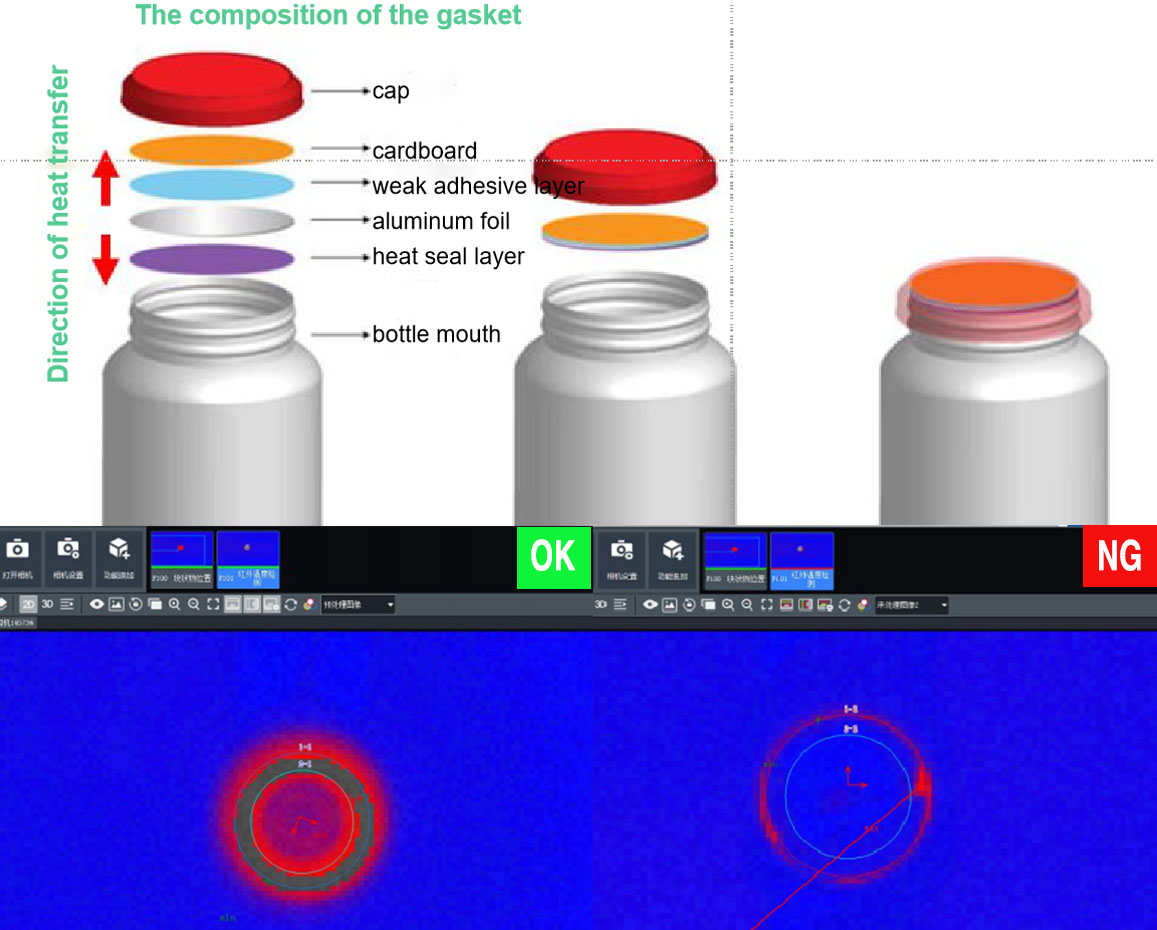

Aluminum foil packaging is widely used in food, pharmaceuticals, and oils, where seal integrity is crucial for product quality. Seal defects like leaks are difficult to detect visually but can lead to spoilage and economic losses, requiring effective inspection.

Solution

Mstar Technologies’ infrared thermal imaging camera accurately maps the heat distribution to identify sealing defects. It monitors temperature differences between sealed and unsealed areas, ensuring proper seal formation. The image below shows a properly sealed bottle neck as a complete ring, while defects are visible as gaps or uneven foil melting. The system integrates image recognition and automation for intelligent sealing inspection.

Benefits

- Non-contact Inspection: No physical contact with the product, preventing damage or contamination.

- Efficient and Accurate: Quickly detects defects using infrared technology and AI on high-speed lines.

- Intelligent Integration: Real-time feedback and collaboration with other production line equipment.