Background

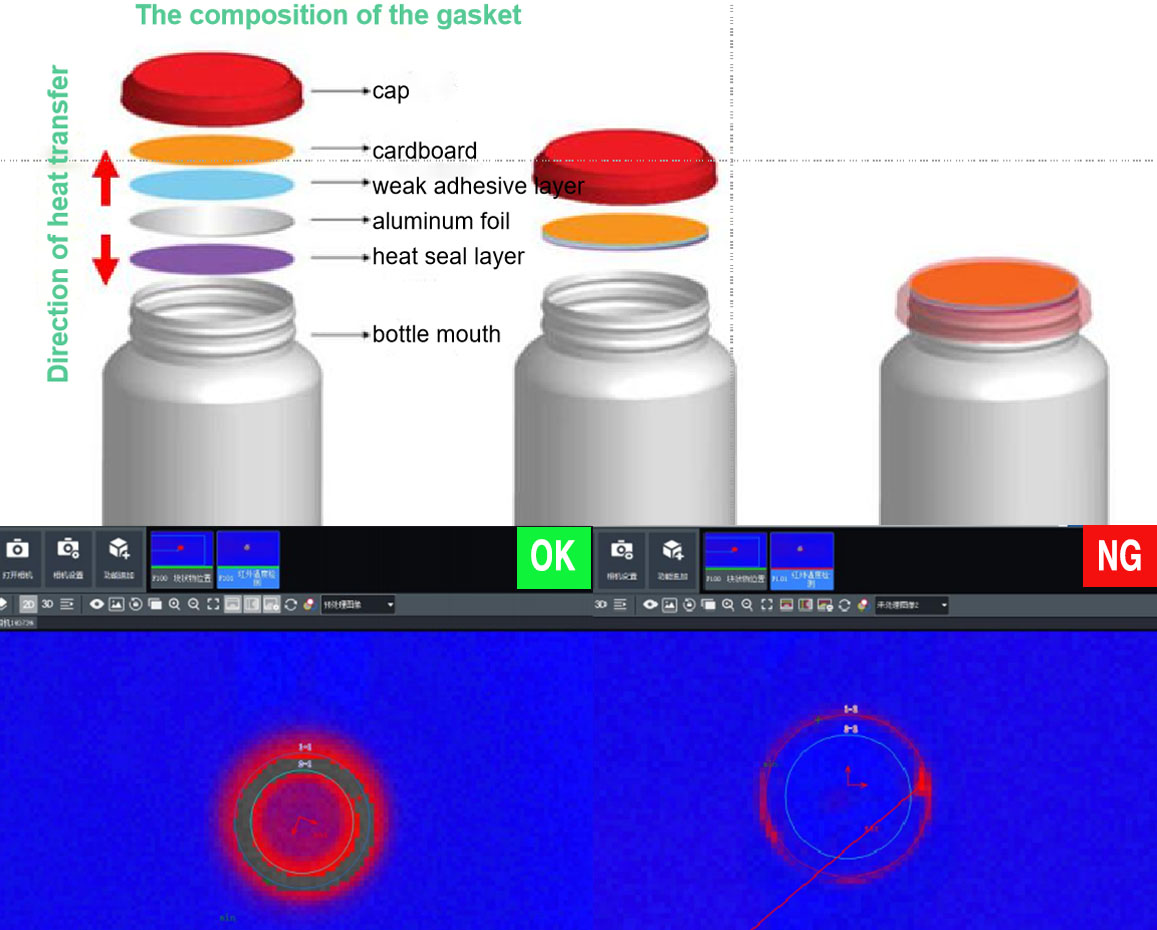

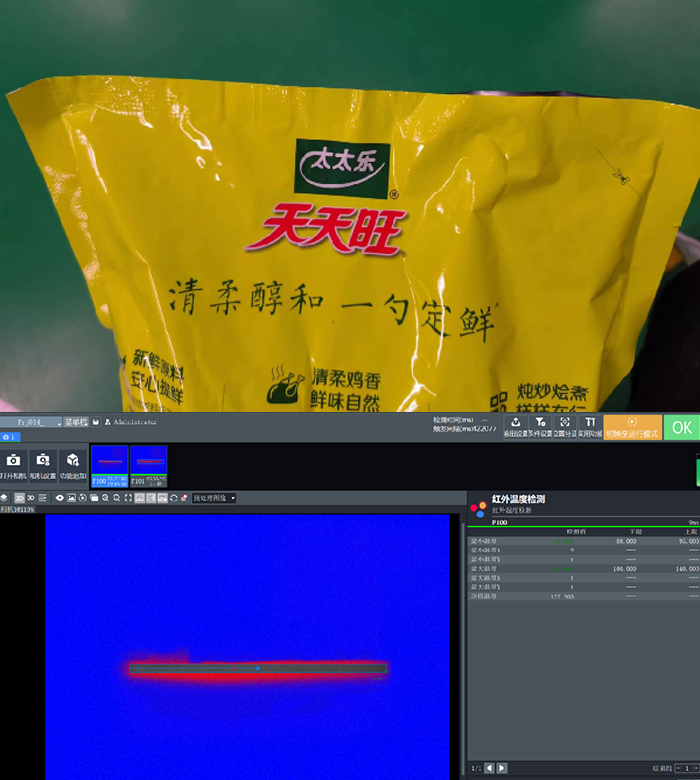

In food packaging, heat sealing is used to create an airtight environment that protects the contents by isolating oxygen and water vapor, preventing leaks and contamination. The sealing quality directly impacts the protective function of the packaging. During the heat-sealing process, improper settings of temperature, pressure, or time can result in poor sealing, weak seals, or over-sealing, leading to issues such as leaks, unsealed openings, or ruptures.

Solution

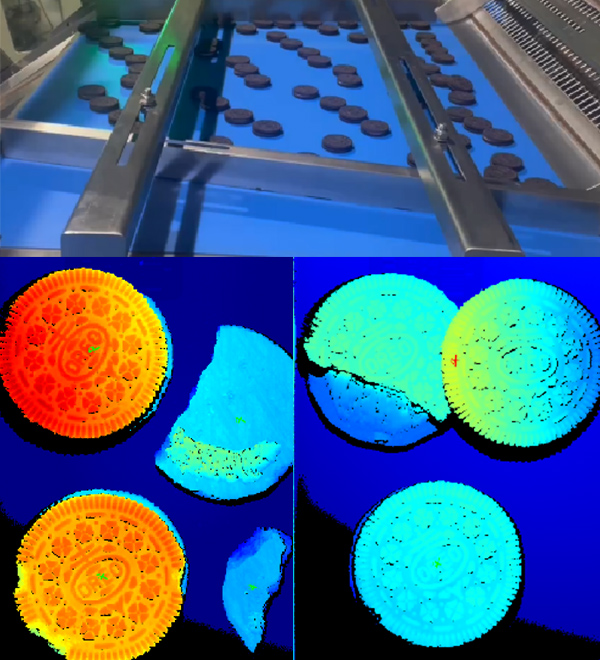

Mstar Technologies' infrared thermal imaging system uses thermal imaging to generate pseudo-color patterns of heat-sensitive regions, analyzing image area and dimensions to identify potential sealing defects. By evaluating the area and shape, the system can detect skewed triangular seals; temperature ranges are analyzed to determine material entrapment at the seal; and regional temperature variations are measured via software to detect weak seals. Mstar's infrared thermal imaging ensures production stability and product sealing integrity.

Benefits

- Real-Time Monitoring and Efficient Detection: Infrared thermal imaging captures temperature changes during the sealing process in real time, providing immediate feedback to identify sealing defects and prevent defective products from entering the market.

- High Sensitivity and Accuracy: Sensitive to temperature variations, the system precisely identifies temperature distributions in the heat-sealing area, detecting potential issues such as low temperature, overheating, or uneven seals.

- Non-Destructive and Highly Automated: As a non-contact technology, infrared thermal imaging does not damage packaging and integrates with image recognition for automated inspection, enhancing efficiency and reducing human errors.