Background

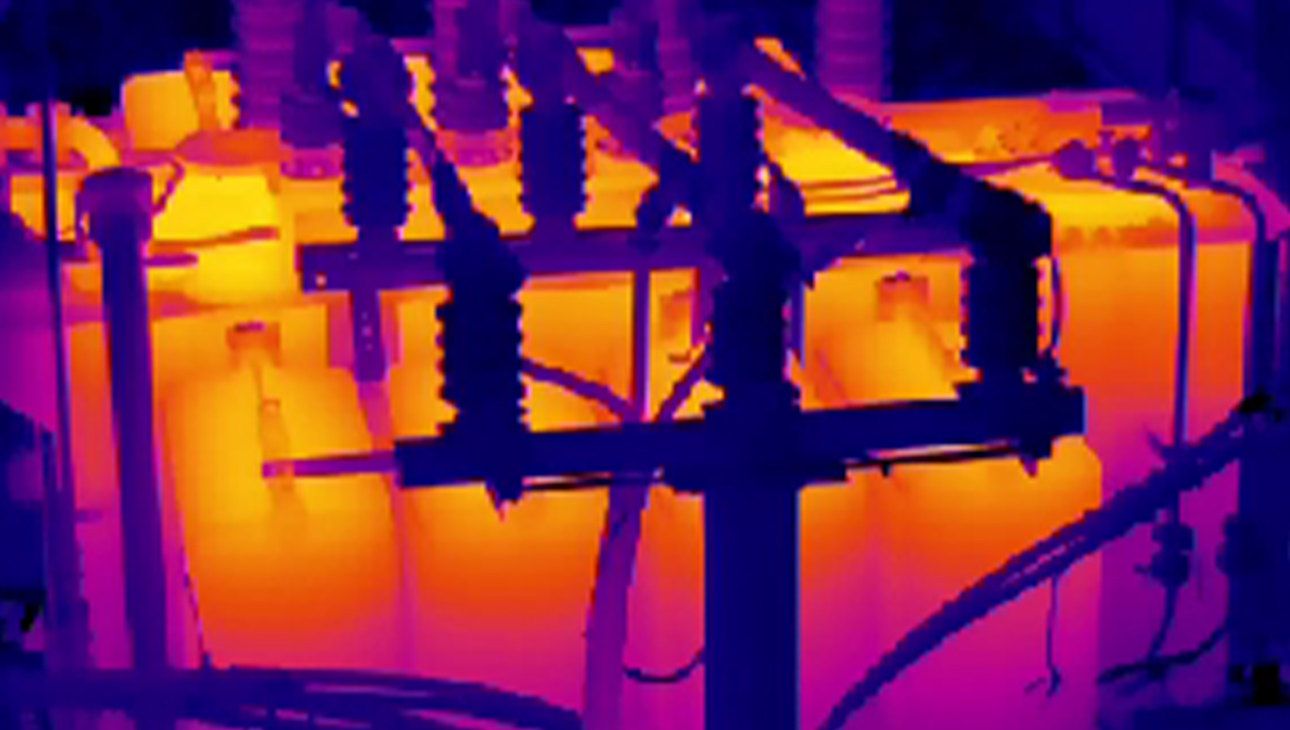

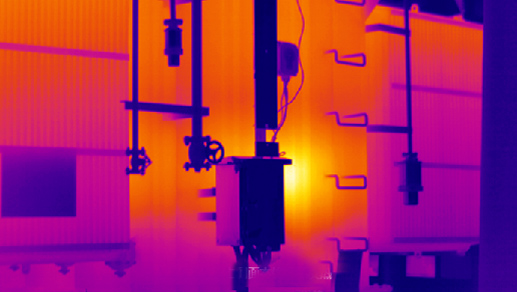

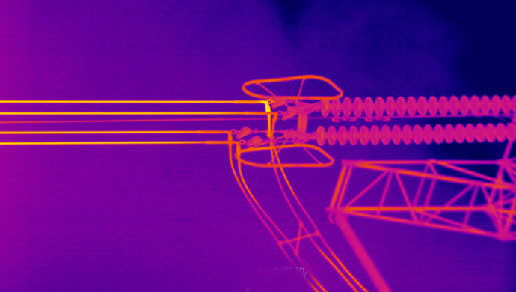

Distribution cabinets play a critical role in ensuring the stable delivery of electrical power. However, faults such as poor terminal connections or loose busbar joints frequently lead to overheating. If these issues remain undetected, they can degrade insulation, resulting in severe consequences, including short circuits, grounding faults, equipment damage, power outages, and heightened safety risks. Proactive temperature monitoring is essential to address these challenges and prevent system failures.

Solution

The IR-CAMS600 and HD-E600G-25 thermal imaging devices provide effective solutions for monitoring terminal blocks and other critical components within distribution cabinets. These advanced tools enable technicians to detect temperature anomalies early, ensuring the timely identification and resolution of potential faults.

Benefits

- Early Fault Detection: Thermal imaging reveals overheating issues caused by loose connections or poor insulation before they escalate into major problems.

- Enhanced Safety: Non-contact inspection ensures safe monitoring of live equipment without the risk of electrical hazards.

- Minimized Downtime: Quick identification of faults reduces repair times and prevents costly power outages.

- Cost-Effective Maintenance: Preventive monitoring extends equipment lifespan, lowering maintenance and replacement costs.

The IR-CAMS600 and HD-E600G-25 provide reliable, efficient solutions for monitoring terminal blocks and components in distribution cabinets. These tools help detect faults early, enhance safety, and ensure system reliability while minimizing downtime and maintenance costs.