Background

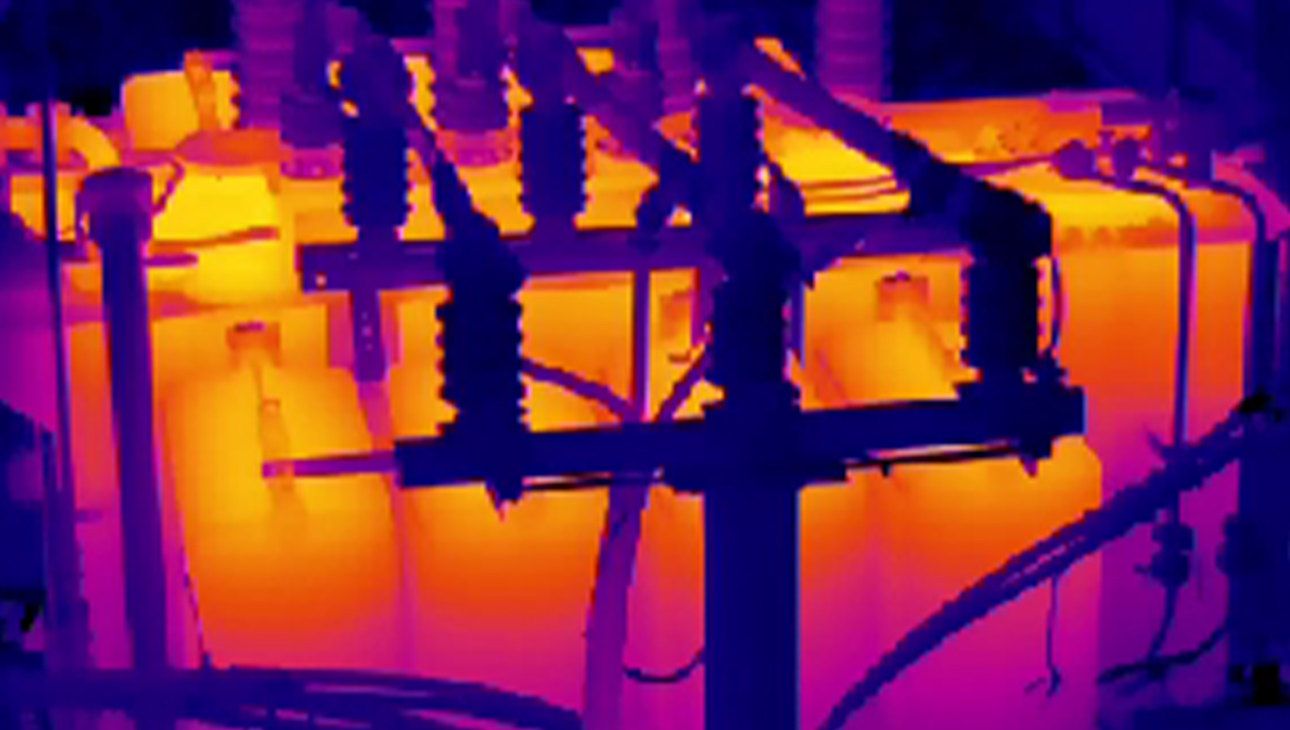

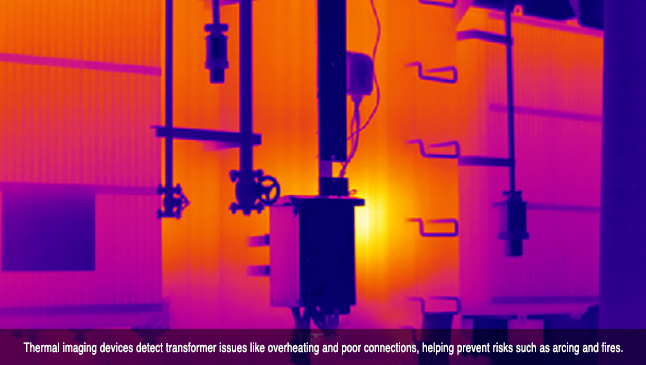

Transformers are prone to issues such as loose connections, poor contact, unbalanced loads, overloading, and overheating. These hidden dangers can lead to severe consequences, including arcing, short circuits, equipment burnout, or even fires. Traditional inspection methods often fail to detect these problems early, posing challenges for ensuring transformer safety and reliability.

Solution

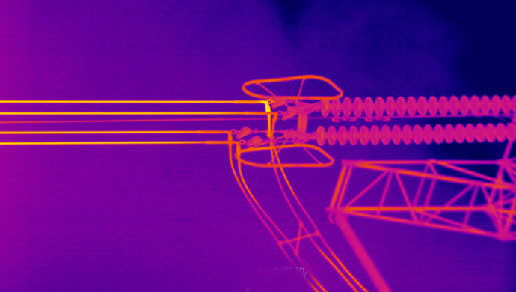

Thermal imaging devices like the HD-E600G-25 handheld thermal imager and the HCIR-DSQ-A600 fixed thermal camera offer a reliable, non-invasive solution. By providing clear infrared imaging, these devices enable engineers to quickly identify and address potential issues, such as overheating or load imbalances.

Benefits

- The HD-E600G-25 detected an overheating connection point during routine inspections, allowing timely repairs and preventing equipment damage.

- The HCIR-DSQ-A600, used for continuous monitoring, provided early alerts of load imbalances, reducing downtime and ensuring safe operation.

- Early Detection: Identifies potential faults before they escalate.

- Enhanced Safety: Enables non-contact inspections, reducing risks to personnel.

- Improved Efficiency: Minimizes downtime and maintenance costs.

Thermal imaging technology ensures reliable and efficient transformer performance, protecting critical infrastructure and reducing operational risks.