Background

In the research and development and production process of smart toilet seats, ensuring the stability and safety of the heating function is crucial. Traditional testing methods usually rely on thermocouples and single-point temperature measurement, which can only obtain limited temperature data and make it difficult to comprehensively evaluate the temperature distribution of the toilet seat heating wire and the overall surface.

Solution

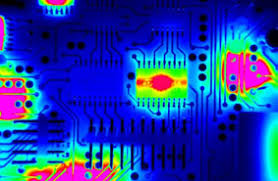

The infrared thermal imaging testing solution can be widely used in various links such as smart toilet seat production testing, product development, and quality control to ensure that the heating performance of the product meets safety, comfort, and energy-saving standards and improve user experience.

By using infrared thermal imaging technology, companies can not only improve the accuracy and efficiency of testing, but also optimize the heating design, reduce the product failure rate, and provide higher-quality smart bathroom products for the market.

Benefits

- Overall temperature distribution visualization: Infrared thermal imaging can generate a complete temperature distribution map, visually presenting the heating uniformity and avoiding problems such as local overheating or uneven temperature.

- Improved detection efficiency: Without the need for multi-point sensor layout, a single scan can complete the detection, greatly shortening the test time and improving production efficiency.

- Non-contact measurement: It avoids the errors or damage that may be caused by the contact of traditional detectors with the product, and is suitable for production lines and quality inspection.