Background

In the electronics manufacturing industry, the quality of circuit boards directly impacts the performance and stability of products. Traditional inspection methods mainly rely on manual visual checks or contact-based measurements, which are inefficient and unable to cover all potential failure points. To improve inspection accuracy and efficiency, an increasing number of companies are adopting infrared thermal imaging technology for real-time monitoring and analysis of circuit boards.

Solution

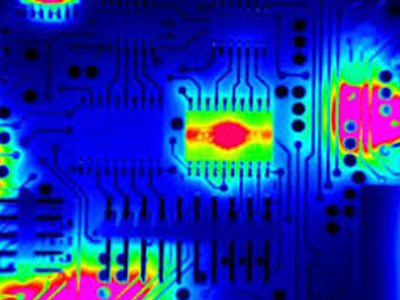

Infrared thermal imaging technology captures thermal radiation data from the circuit board in real-time and generates clear temperature distribution maps. Through these thermal images, engineers can intuitively observe temperature variations in different areas of the circuit board and identify potential anomalies. For instance, a properly functioning circuit board should have a uniform temperature distribution, while faulty boards may exhibit abnormally high or low temperatures in specific regions. These anomalies are typically linked to poor contact, component damage, or soldering defects on the board.

Benefits

- Non-Contact Inspection: Unlike traditional contact-based measurements that may damage the circuit board, infrared thermal imaging provides non-contact inspection, avoiding physical interference with components.

- Reduced Defect Rate: By conducting real-time monitoring during production, potential issues can be identified and corrected promptly, preventing defective products from reaching the market.

- Improved Inspection Efficiency: Traditional manual inspection methods require checking individual components on the circuit board, which is time-consuming. Infrared thermal imaging can scan the entire board’s temperature in just seconds, significantly speeding up the inspection process.