Background

The packaging industry typically involves multiple processes before products are shipped. Automating these processes as much as possible helps ensure efficiency, improve consistency, and prevent errors. In this application, the final step of the packaging process involves sealing cartons with hot melt adhesive. The position, quantity, and shape of the adhesive directly affect the seal integrity, making inspection essential.

Solution

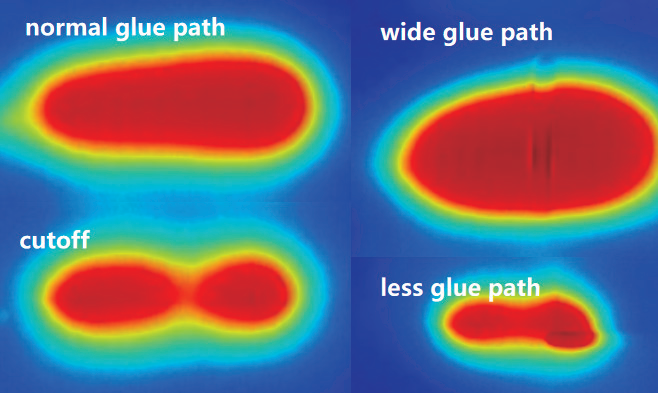

Mstar Technologies' infrared thermal imaging system has been implemented on a leading beer production line to inspect the accuracy of adhesive application during carton sealing. When a single cardboard sheet is folded into a box, hot melt adhesive is applied to join the flaps. However, the adhesive is covered by the cardboard, making it invisible to visible light systems. By using Mstar's infrared thermal imaging cameras, the adhesive application can be effectively monitored, ensuring accurate and reliable adhesive inspection.

Benefits

- Real-Time Monitoring: Captures the temperature distribution and application status of hot melt adhesive in real time, improving inspection efficiency.

- High Sensitivity: Detects subtle temperature variations to identify uneven distribution, missing, or excessive adhesive quickly.

- Intelligent Integration: Combines image recognition and automation to enable online monitoring and automatic sorting, enhancing production line intelligence.